slewing bearing

-

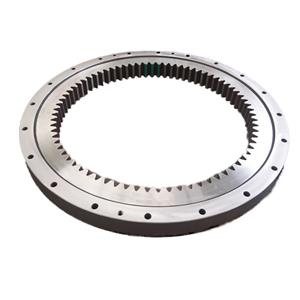

Single Row Cross Roller Slewing Ring Turntable Bearing (HJ Series)

The single-row cross-roller slewing bearing consists of two rings, with compact structure, high manufacturing accuracy, small assembly clearance, and high requirements for installation accuracy. It can bear overturning moment and large radial force and it is widely used in transportation, construction machinery and military products. There are two basic working modes: 1. The inner ring fixes , and the outer ring rotates; 2. The outer ring fixes and the inner ring rotates. The raceways of the slewing bearing are all treated by surface induction hardening, and the quenching hardness is guaranteed to be HRC55~62, which can achieve sufficient hardened layer depth. Slewing bearing is usually made with internal teeth, external teeth or no teeth. The heat treatment of gears is generally normalized or quenched and tempered. The tooth surface can also be quenched according to the user's requirements, the quenching hardness is HRC50-60, and sufficient depth can be guaranteed. Teeth grinding is also supported.

Email Details -

Single Row Cross Roller Slewing Bearing (11 Series)

The single row cross roller slewing bearing is made of two seat rings. It is featured with compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross- arranged through spacers. It can bear axial force, overturning moment and large radial force at the same time. Compared with ball slewing ring, the axial and radial clearance of the cross roller slewing ring is smaller than single row ball slewing bearing. While the rotating is not so flexible as the single row ball slewing bearings, usually it is used for some higher precision applications. It is widely used in lifting transportation, construction machinery, military product, robots, medical equipment, grinding and drilling machine etc. Standard material we adopt is 50Mn and 42CrMo. Other customized material is also acceptable. We support models selection based on your application; teeth quenching and grinding; customized surface treatment like Blackening, phosphating, galvanizing, sandblasting and etc.

Email Details -

High Precision Slewing Bearing For Filling Machine

Light series slewing bearings are usually used on filling machine, which has the same structure as ordinary slewing bearing, but it has the characteristics of lightweight, flexible rotation, compact structure and low friction. This kind of slewing ring bearing is widely used in food machinery, filling machinery, beverage machinery, blow molding machine, packaging machinery, injection molding machine, environmental protection machinery, and other fields. It is with features of low noise, high precision and high performance. Adhering to the international advanced management concept, we are committed to providing a complete set of bearing solutions, from raw material control, rolling element, cage and anti-rust oil, grease, bearing lathe processing, heat treatment to rough grinding and fine grinding, bearing packaging and delivery, after-sales service , installation guidance, all-round service in accordance with international standards

slewing gear bearing slewing bearings suppliers slewing bearing manufacturers slewing bearing with external gearEmail Details -

Single Row Four Point Contact Ball Slewing Bearing( 01 Series)

Single row four point contact ball slewing bearing 01 series is a standard model series in China. It is made of two seat rings. The balls and the raceway are with four points contact, via which the axial force, radial force and resultant moment is born simultaneously. Outer Diameter is from 280mm to 4726mm. Most models slewing ring are with ready stock or semi-finished material stock, which can deliver out within 15 days. Standard material we adopt is 50Mn and 42CrMo. Other customized material is also acceptable. We support models selection based on your application; teeth quenching and grinding; customized surface treatment like Blackening, phosphating, galvanizing, sandblasting and etc. In the production process of slewing ring bearing, whole process inspection is implemented strictly to ensure that each set of products are qualified. For high-precision products, precise grinding is used to effectively control the parameters of ring ellipse, wall thickness and flatness, so as to ensure that the precision of finished products meets the requirements of standards or customer drawings. This series models are with advantage of compact design, flexible rotating and light weight. It is widely used on rotary conveyor, welding arm and positioner, light/medium duty cranes, excavators and other engineering machines. Please feel free to tell us the application you use and we can help you choose the proper model and offer you a professional solution as soon as possible.

slew bearing with external gear truck crane slewing bearing tower crane slewing bearing mobile crane slewing bearingEmail Details -

Pitch Bearing Of Wind Turbine Generator

The material pitch bearing rings is 42CrMo, the heat treatment adopts the overall quenching and tempering treatment, and the surface of the raceway is quenched. The force of pitch bearings is complex, and the impact and vibration are relatively large. Therefore, the bearing is required to withstand both impact and large load. The life of the wind turbine main engine is required to be 20 years, and the cost of bearing installation is relatively large, so the life of the yaw and pitch bearings is required to reach 20 years. The hardness of the bearing ring base is 240-280HB, which can withstand impact without plastic deformation. At the same time, the surface quenching hardness of the raceway reaches 55-62HRC, which can increase the contact fatigue life and ensure the service life of the bearing.

Email Details -

Swing Bearing For Hyundai

Excavator is one of the important equipment in modern engineering construction. The reason why the excavator can turn left and right in the work is inseparable from the credit of the slewing mechanism, which is one of the important components of the hydraulic excavator. The slewing mechanism is connected with the traveling device through a slewing bearing, and the slewing drive device makes the platform rotate relative to the traveling device, and drives the working device to rotate around its central axis of rotation. We are specialized in the production of engineering machinery slewing bearings, drive shafts and matched pinions. For some common model excavators slewing bearing, we have ready stock and can deliver within one week. Our company has a special quality testing laboratory, devoted to product design and development, product application and testing methods. At the same time, the company also has advanced production equipment and testing equipment to ensure that products have high performance, long life, low friction, high precision.

Email Details -

Swing Bearing For JCB

Excavator is one of the important equipment in modern engineering construction. The reason why the excavator can turn left and right in the work is because of the slewing mechanism, which is one of the important components of the hydraulic excavator. The slewing mechanism is connected with the traveling device through a slewing bearing, and the slewing drive device makes the platform rotate relative to the traveling device, and drives the working device to rotate around its central axis of rotation. We are specialized in the production of engineering machinery slewing bearings, drive shafts and matched pinions. For some common model excavators slewing bearing, we have ready stock and can deliver within one week. Our company has a special quality testing laboratory, devoted to product design and development, product application and testing methods. At the same time, the company also has advanced production equipment and testing equipment to ensure that products have high performance, long life, low friction, high precision.

Email Details -

Swing Bearing For Yuchai

Slewing ring is widely used in construction equipment like excavators. It is wear parts. We are specialized in the production of engineering machinery slewing bearings, drive shafts and matched pinions. If you need replacements of the steel balls, rollers or spacers, it is also available. For some common model excavators slewing bearing, we have ready stock and can deliver within one week. If you have old slewing bearing in hand, we can instruct you to measure the detailed size to make a professional drawing and then manufacture it for you. Our company has a special quality testing laboratory, devoted to product design and development, product application and testing methods. At the same time, the company also has advanced production equipment and testing equipment to ensure that products have high performance, long life, low friction, high precision.

Email Details -

Standard Double Row Ball Slewing Bearing

The double row ball slewing bearing has three seat rings. The steel balls and isolators can be directly arranged into the upper and lower raceways. According to the stress conditions, the upper and lower rows of steel balls with different diameters are arranged. This kind of open assembly is very convenient. The bearing angle of the upper and lower arc raceway is 75 degrees. It can bear a great deal of axial force and overturning moment. When the radial force is greater than 0.1 times the axial force, the raceway must be specially designed. The axial and radial dimensions of the double row ball slewing bearing are relatively large and the structure is fastened. It is especially suitable for handling tower cranes, truck cranes and other loading machines that require medium or above diameters, military products. The double-row four-point contact ball slewing bearing structure is similar to the single-row ball slewing bearing, the difference is that it uses two rows of steel balls as rolling elements, the two rows of steel balls have the same size, and a single isolation block is set between the steel balls. The inner and outer rings are integral, and the steel balls are loaded by plugging the holes. It requires a product for a heavy-duty, radially constrained host. Double row different diameter ball slewing bearing structure is characterized by the upper and lower double-row steel balls, inner and outer rings, isolation blocks and lubrication and sealing devices. However, the double-row different diameter slewing bearing is a three-piece slewing bearing, and its structure is more complicated.

Email Details