Single Row Cross Roller Slewing Ring Turntable Bearing (HJ Series)

- LYHGB

- Luoyang

- 45 days

- 4000 sets/ month

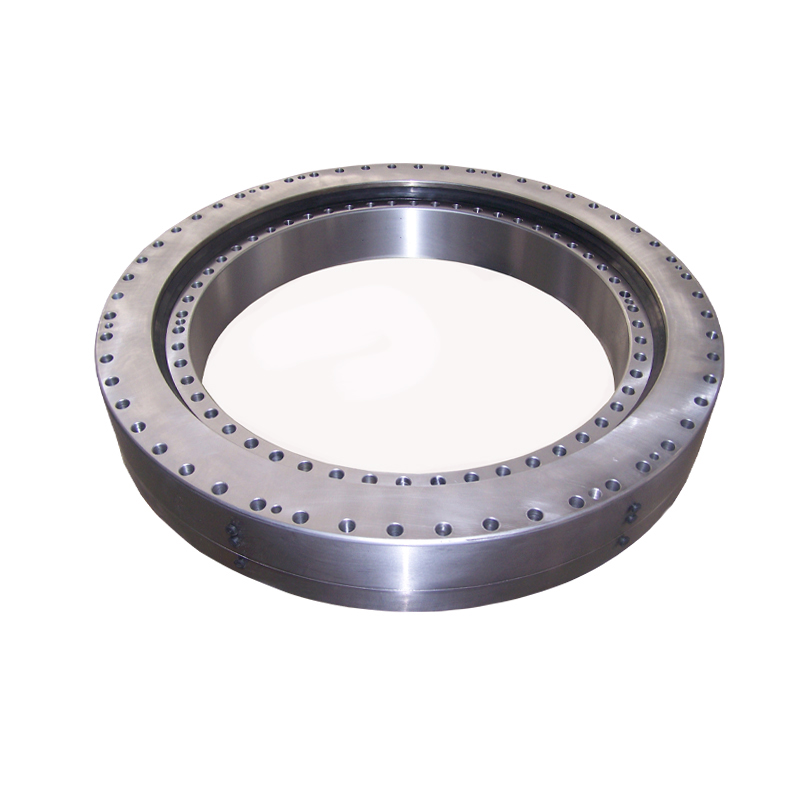

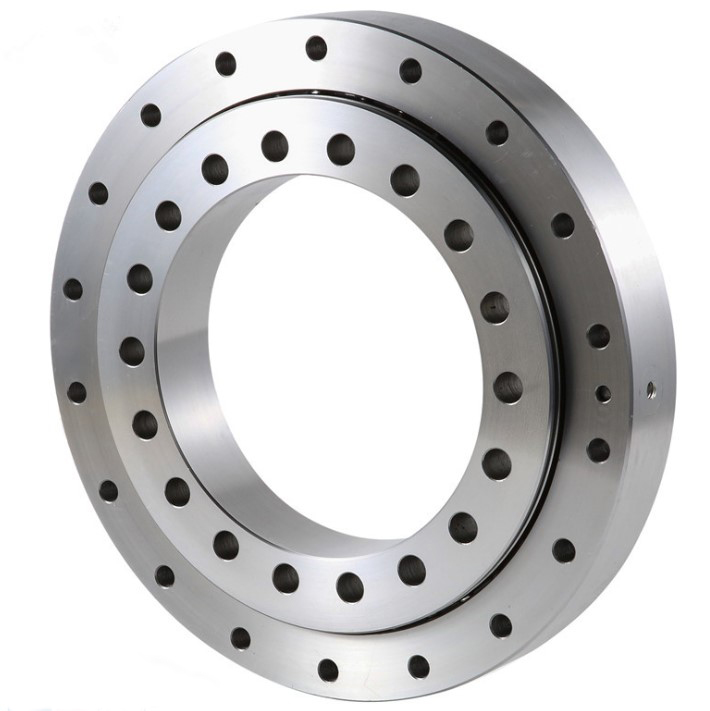

The single-row cross-roller slewing bearing consists of two rings, with compact structure, high manufacturing accuracy, small assembly clearance, and high requirements for installation accuracy. It can bear overturning moment and large radial force and it is widely used in transportation, construction machinery and military products.

There are two basic working modes: 1. The inner ring fixes , and the outer ring rotates; 2. The outer ring fixes and the inner ring rotates. The raceways of the slewing bearing are all treated by surface induction hardening, and the quenching hardness is guaranteed to be HRC55~62, which can achieve sufficient hardened layer depth.

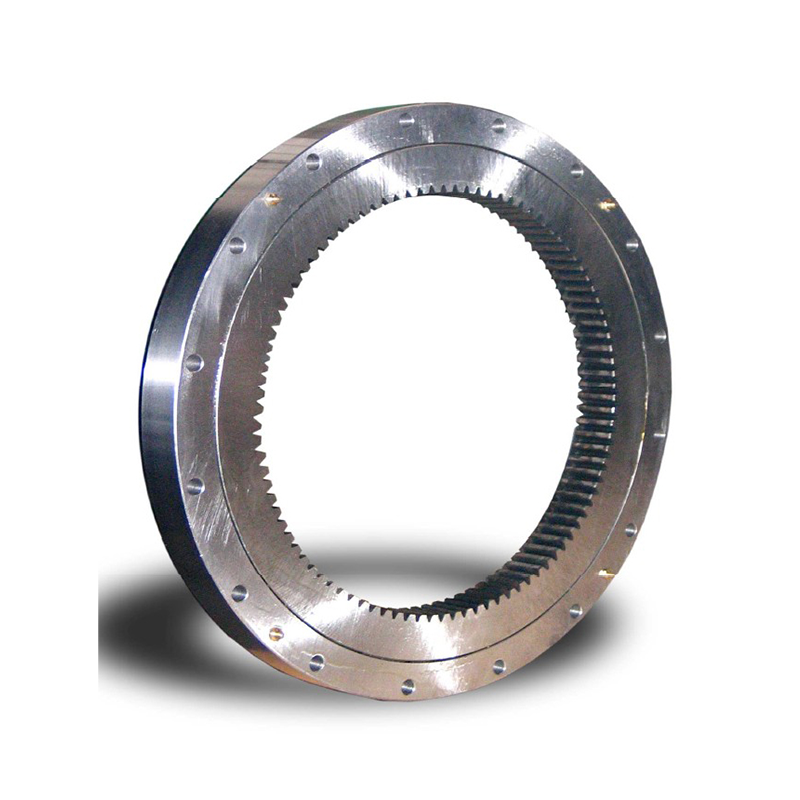

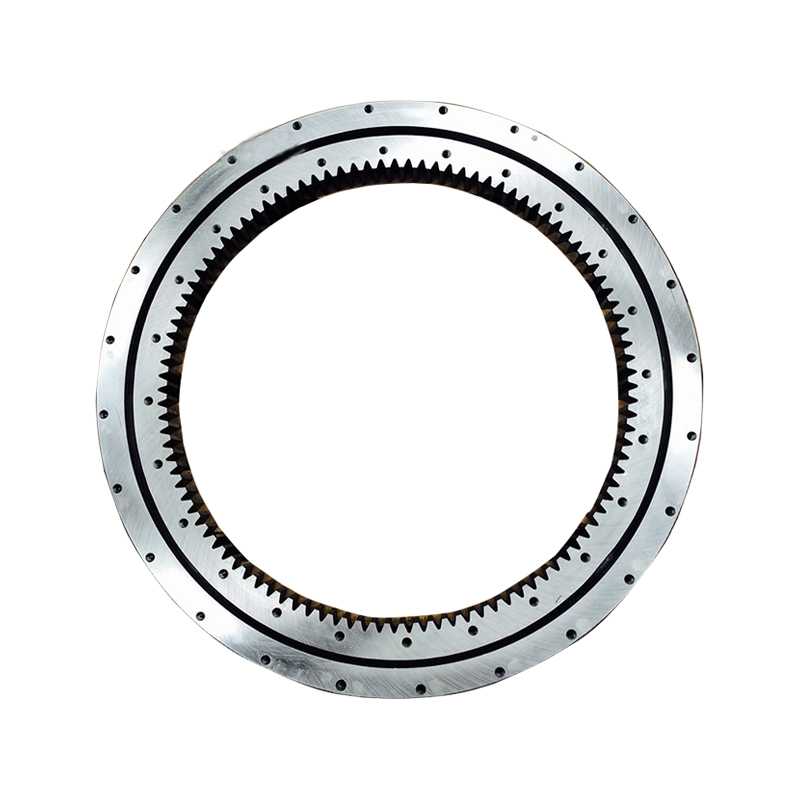

Slewing bearing is usually made with internal teeth, external teeth or no teeth. The heat treatment of gears is generally normalized or quenched and tempered. The tooth surface can also be quenched according to the user's requirements, the quenching hardness is HRC50-60, and sufficient depth can be guaranteed. Teeth grinding is also supported.

Single Row Cross Roller Slewing Ring (HJ Series)

The single-row cross-roller slewing bearing consists of two rings, with compact structure, high manufacturing accuracy, small assembly clearance, and high requirements for installation accuracy. It can bear overturning moment and large radial force and it is widely used in transportation, construction machinery and military products.

The satandard slewing bearing numbering method

x x x xx xxxx x

- - - -- ---- -

(1) (2) (3) (4) (5) (6)

(1) Slewing bearing code H

(2) Product category

J cross roller type

S single row four point contact ball type

(3) Driving mode

No gear

External gear

Internal gear

(4) Rolling body diameter: Steel ball or cylindrical roller mm

(5) Raceway center diameter

(6) Gear modulus code

A-Large module

without A: small module

Technical parameters

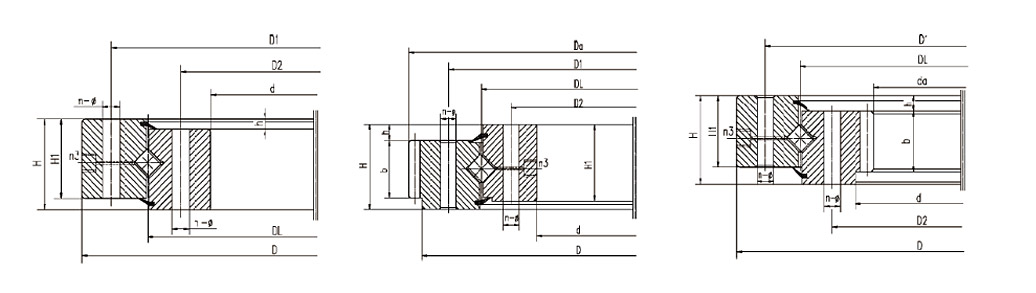

| Bearing type | Boundary dimensions | Mounting hole diameter | Structure dimensions | Gear parameters | Mass KG | |||||||||||||||||

| Non-gear type | External gear type | Internal gear type | D | d | H | D1 | D2 | n | φ | DL | H1 | h | n3 | b | m | Ext gear | Int gear | |||||

| mm | mm | mm | mm | mm | x | Da mm | Z | x | da mm | Z | ||||||||||||

| HJB.20.625 | HJW.20.625 | HJN.20.625 | 725 | 525 | 80 | 685 | 565 | 18 | 18 | 625 | 68 | 12 | 3 | 60 | 5 | +1.25 | 752 | 146 | +0.35 | 498.8 | 101 | 100 |

| HJW.20.625A | HJN.20.625A | 6 | +1.00 | 756 | 122 | +0.35 | 496.7 | 84 | ||||||||||||||

| HJB.20.720 | HJW.20.720 | HJN.20.720 | 820 | 620 | 80 | 780 | 660 | 18 | 18 | 720 | 68 | 12 | 3 | 60 | 6 | +1.25 | 860 | 139 | +0.35 | 586.6 | 99 | 120 |

| HJW.20.720A | HJN.20.720A | 8 | +0.85 | 861 | 104 | +0.35 | 582.3 | 74 | ||||||||||||||

| HJB.30.820 | HJW.30.820 | HJN.30.820 | 940 | 705 | 95 | 893 | 749 | 24 | 20 | 820 | 83 | 12 | 4 | 70 | 6 | +1.25 | 980 | 159 | +0.35 | 664.5 | 112 | 210 |

| HJW.30.820A | HJN.30.820A | 10 | +0.85 | 986 | 95 | +0.35 | 658 | 67 | ||||||||||||||

| HJB.30.880 | HJW.30.880 | HJN.30.880 | 1000 | 760 | 95 | 956 | 800 | 24 | 20 | 880 | 83 | 12 | 4 | 70 | 8 | +1.0 | 1048 | 127 | +0.35 | 718.2 | 91 | 230 |

| HJW.30.880A | HJN.30.880A | 10 | +0.85 | 1046 | 101 | +0.35 | 707.9 | 72 | ||||||||||||||

| HJB.30.1020 | HJW.30.1020 | HJN.30.1020 | 1170 | 875 | 95 | 1120 | 930 | 24 | 22 | 1020 | 80 | 15 | 4 | 70 | 8 | +1.25 | 1219 | 148 | +0.35 | 830.1 | 105 | 300 |

| HJW.30.1020A | HJN.30.1020A | 10 | +1.00 | 1219 | 118 | +0.35 | 827.8 | 84 | ||||||||||||||

| HJB.36.1220 | HJW.36.1220 | HJN.36.1220 | 1365 | 1075 | 120 | 1310 | 1130 | 36 | 24 | 1220 | 105 | 15 | 6 | 90 | 10 | +1.25 | 1425 | 138 | +0.35 | 1027.8 | 104 | 450 |

| HJW.36.1220A | HJN.36.1220A | 12 | +0.85 | 1436 | 116 | +0.35 | 1017.3 | 86 | ||||||||||||||

| HJB.36.1435 | HJW.36.1435 | HJN.36.1435 | 1595 | 1278 | 120 | 1535 | 1335 | 36 | 26 | 1435 | 105 | 15 | 6 | 90 | 12 | +1.0 | 1656 | 134 | +0.35 | 1221.1 | 103 | 610 |

| HJW.36.1435N | HJN.36.1435N | 14 | +0.85 | 1661 | 115 | +0.35 | 1214.8 | 88 | ||||||||||||||

| HJB.45.1540 | HJW.45.1540 | HJN.45.1540 | 1720 | 1360 | 140 | 1660 | 1420 | 42 | 26 | 1540 | 122 | 18 | 6 | 110 | 12 | +1.4 | 1781 | 144 | +0.35 | 1293.1 | 109 | 732 |

| HJW.45.1540N | HJN.45.1540N | 14 | +1.0 | 1791 | 124 | +0.35 | 1284.8 | 93 | ||||||||||||||

| HJB.45.1700 | HJW.45.1700 | HJN.45.1700 | 1875 | 1525 | 140 | 1815 | 1585 | 42 | 29 | 1700 | 122 | 18 | 6 | 110 | 14 | +1.0 | 1945 | 135 | +0.35 | 1452.7 | 105 | 844 |

| HJW.45.1700A | HJN.45.1700A | 16 | +1.0 | 1951 | 118 | +0.35 | 1452.3 | 92 | ||||||||||||||

| HJB.45.1880 | HJW.45.1880 | HJN.45.1880 | 2100 | 1665 | 160 | 2030 | 1740 | 48 | 32 | 1880 | 140 | 20 | 6 | 115 | 14 | +1.25 | 2190 | 152 | +0.35 | 1592.6 | 115 | 1400 |

| HJW.45.1880A | HJN.45.1880A | 18 | +1.0 | 2195 | 118 | +0.35 | 1579.9 | 89 | ||||||||||||||

| HJB.45.2115 | HJW.45.2115 | HJN.45.2115 | 2325 | 1900 | 160 | 2245 | 1980 | 48 | 32 | 2115 | 140 | 20 | 6 | 115 | 16 | +1.25 | 2407 | 146 | +0.35 | 1804.1 | 114 | 1600 |

| HJW.45.2115A | HJN.45.2115A | 20 | +1.0 | 2418 | 117 | +0.35 | 1795.4 | 91 | ||||||||||||||

| HJB.45.2370 | HJW.45.2370 | HJN.45.2370 | 2600 | 2146 | 180 | 2520 | 2220 | 48 | 32 | 2370 | 158 | 22 | 6 | 130 | 18 | +1.25 | 2307 | 146 | +0.35 | 2065.6 | 116 | 2100 |

| HJW.45.2370A | HJN.45.2370A | 22 | +1.0 | 2704 | 119 | +0.35 | 2040.9 | 94 | ||||||||||||||

| HJB.45.2600 | HJW.45.2600 | HJN.45.2600 | 2835 | 2365 | 180 | 2750 | 2450 | 54 | 36 | 2600 | 158 | 22 | 6 | 130 | 18 | +1.25 | 2942 | 159 | +0.35 | 2263.5 | 127 | 2400 |

| HJW.45.2600A | HJN.45.2600A | 22 | +1.0 | 2947 | 130 | +0.35 | 2260.8 | 104 | ||||||||||||||

| HJB.50.2820 | HJW.50.2820 | HJN.50.2820 | 3085 | 2555 | 200 | 3000 | 2640 | 54 | 36 | 2820 | 178 | 22 | 6 | 150 | 20 | +1.25 | 3188 | 155 | +0.35 | 2455 | 124 | 3400 |

| HJW.50.2820A | HJN.50.2820A | 25 | +1.0 | 3198 | 124 | +0.35 | 2444.1 | 99 | ||||||||||||||

| HJB.50.3120 | HJW.50.3120 | HJN.50.3120 | 3400 | 2840 | 200 | 3310 | 2930 | 54 | 36 | 3120 | 178 | 22 | 6 | 150 | 22 | +1.25 | 3507 | 155 | +0.35 | 2722 | 125 | 4000 |

| HJW.50.3120A | HJN.50.3120A | 25 | +1.25 | 3510 | 136 | +0.35 | 2719 | 110 | ||||||||||||||

| HJB.50.3580 | HJW.50.3580 | HJN.50.3580 | 3920 | 3240 | 240 | 3820 | 3340 | 60 | 40 | 3580 | 218 | 22 | 6 | 190 | 22 | +1.25 | 4036 | 179 | +0.35 | 3118.4 | 143 | 6700 |

| HJW.50.3580A | HJN.50.3580A | 25 | +1.25 | 4036 | 157 | +0.35 | 3118.8 | 126 | ||||||||||||||

| HJB.50.4030 | HJW.50.4030 | HJN.50.4030 | 4370 | 3690 | 240 | 4270 | 3790 | 66 | 40 | 4030 | 218 | 22 | 6 | 190 | 22 | +1.25 | 4521 | 201 | +0.35 | 3558.3 | 163 | 7700 |

| HJW.50.4030A | HJN.50.4030A | 28 | +1.25 | 4522 | 157 | +0.35 | 3549 | 128 | ||||||||||||||

| HJB.50.4540 | HJW.50.4540 | HJN.50.4540 | 4860 | 4210 | 240 | 4760 | 4310 | 72 | 40 | 4540 | 218 | 22 | 6 | 190 | 22 | +1.25 | 4983 | 222 | +0.35 | 4042.2 | 185 | 8760 |

| HJW.50.4540A | HJN.50.4540A | 30 | +1.25 | 4993 | 162 | +0.35 | 4042.4 | 136 | ||||||||||||||

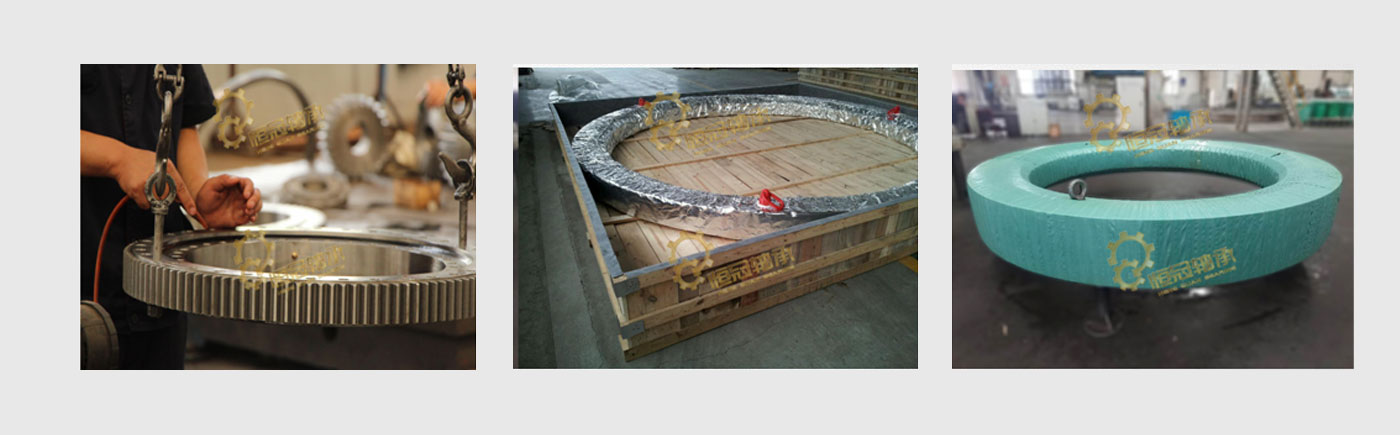

Package

1. Before product packaging, add corresponding brand and type grease according to customer’s requirements to protect raceway from damage.

2. Export wooden boxes suitable for sea transportation are used to ensure the safe arrival of goods at different transportation distances, storage times and regions.

Slewing Bearings Installation Instructions

1. Transportation and Storage of Slewing Bearings

Slewing bearing should be placed horizontally on the vehicle during transportation. Measures should be taken to prevent sliding and vibration. Auxiliary support should be added when necessary. Bearings shall be placed horizontally on dry, ventilated and flat sites, and shall be stored in isolation from chemicals and other corrosive items. If multiple sets of bearings are overlapped, more than three wooden pads of equal height should be evenly placed between each set along the circumferential direction, and the position of upper and lower pads should be the same. Bearings that still need to be stored beyond the anti-rust period should be cleaned and treated again.

2. Installation of Slewing Bearing

Before the installation of slewing bearing, the installation surface of the main engine should be inspected, and the supporting parts should have enough strength, the connection surface should be machined, and the surface should be smooth and free of debris and burrs. In order to ensure the accuracy of the installation plane and to reduce the vibration, the method of filling resin should be adopted for the planarity that can not be machined to meet the requirements. The ring of slewing bearing has quenched soft belt area, which is marked with “S” on the face of the ring. The position of the soft belt should be placed in the non-load area or the non-constant load area (the plug hole is always located in the soft belt area). When installing the slewing bearing, the radial positioning should be carried out first, the installation bolts should be tightened cross-wise, and the rotation of the bearing should be checked. When tightening the bolt, there should be sufficient preload, which should be 70% of the yield limit of the bolt material. Installation bolts should be equipped with conditioned flat washers and spring washers are strictly prohibited.

3. Maintenance of Slewing bearing

After 100 hours of continuous operation, the pre-tightening moment of the bolt should be checked thoroughly, and the above checks should be repeated every 500 hours of continuous operation. When the slewing bearing is installed, proper amount of grease should be filled, Fill the lubricating grease of slewing bearing evenly and rotate at the same time. The slewing bearing will inevitably lose part of the grease after working for a period of time. Therefore, the grease should be added once every 50-100 hours after the normal operation of the slewing bearing.