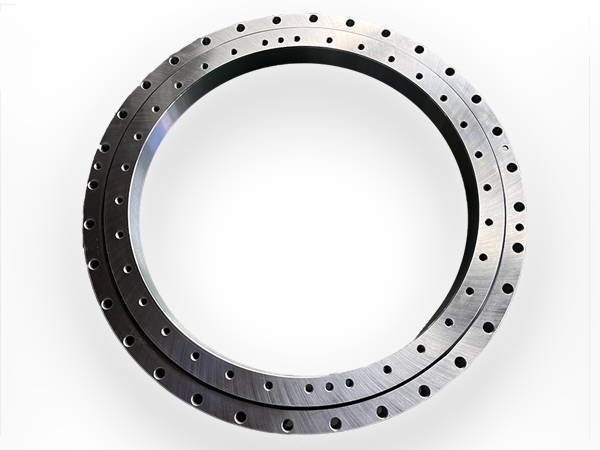

Standard Double Row Ball Slewing Bearing

- LYHGB

- Luoyang

- 45 days

- 1000 sets/ month

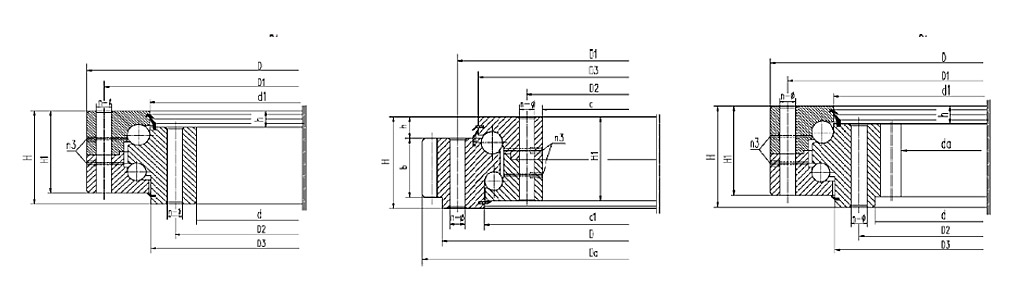

The double row ball slewing bearing has three seat rings. The steel balls and isolators can be directly arranged into the upper and lower raceways. According to the stress conditions, the upper and lower rows of steel balls with different diameters are arranged. This kind of open assembly is very convenient. The bearing angle of the upper and lower arc raceway is 75 degrees. It can bear a great deal of axial force and overturning moment. When the radial force is greater than 0.1 times the axial force, the raceway must be specially designed. The axial and radial dimensions of the double row ball slewing bearing are relatively large and the structure is fastened. It is especially suitable for handling tower cranes, truck cranes and other loading machines that require medium or above diameters, military products.

The double-row four-point contact ball slewing bearing structure is similar to the single-row ball slewing bearing, the difference is that it uses two rows of steel balls as rolling elements, the two rows of steel balls have the same size, and a single isolation block is set between the steel balls. The inner and outer rings are integral, and the steel balls are loaded by plugging the holes. It requires a product for a heavy-duty, radially constrained host.

Double row different diameter ball slewing bearing structure is characterized by the upper and lower double-row steel balls, inner and outer rings, isolation blocks and lubrication and sealing devices. However, the double-row different diameter slewing bearing is a three-piece slewing bearing, and its structure is more complicated.

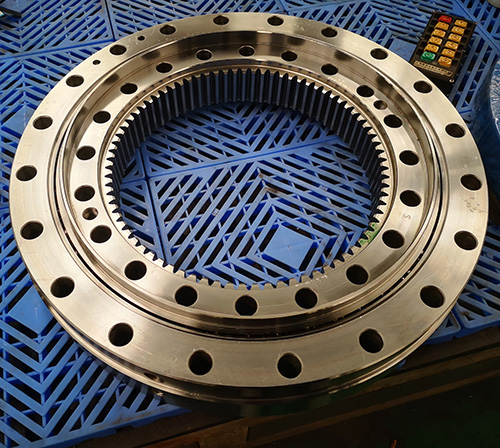

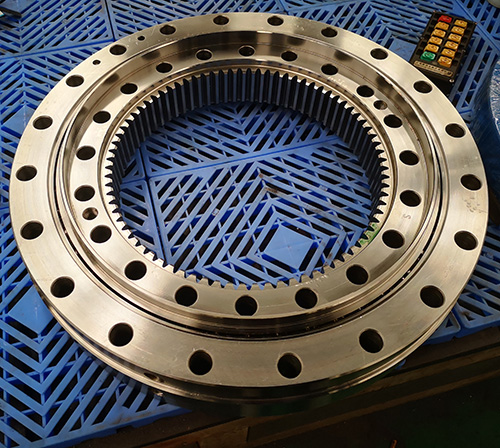

High Precision Double Row Ball Slewing Bearing

The double row ball slewing bearing has three seat rings. The steel balls and isolators can be directly arranged into the upper and lower raceways. According to the stress conditions, the upper and lower rows of steel balls with different diameters are arranged. This kind of open assembly is very convenient. The bearing angle of the upper and lower arc raceway is 75 degrees. It can bear a great deal of axial force and overturning moment. When the radial force is greater than 0.1 times the axial force, the raceway must be specially designed. The axial and radial dimensions of the double row ball slewing bearing are relatively large and the structure is fastened. It is especially suitable for handling tower cranes, truck cranes and other loading machines that require medium or above diameters, military products.

The double-row four-point contact ball slewing bearing structure is similar to the single-row ball slewing bearing, the difference is that it uses two rows of steel balls as rolling elements, the two rows of steel balls have the same size, and a single isolation block is set between the steel balls. The inner and outer rings are integral, and the steel balls are loaded by plugging the holes. It requires a product for a heavy-duty, radially constrained host.

Double row different diameter ball slewing bearing structure is characterized by the upper and lower double-row steel balls, inner and outer rings, isolation blocks and lubrication and sealing devices. However, the double-row different diameter slewing bearing is a three-piece slewing bearing, and its structure is more complicated.

Technical Parameters

| Bearing type | Boundary dimensions | Mounting hole diameter | Structure dimensions | Gear parameters | Mass KG | |||||||||||||||||

| Non-gear type | External gear type | Internal gear type | D | d | H | D1 | D2 | n | φ | D3 | d1 | H1 | H | n3 | m | Ext gear | Int gear | b | x | |||

| mm | mm | mm | mm | Da | Z | da | Z | mm | ||||||||||||||

| 020.25.500.** | 021.25.500.** | 023.25.500.** | 616 | 384 | 106 | 580 | 420 | 20 | 18 | 523 | 517 | 96 | 26 | 4/M10*1 | 5 | 645 | 126 | 355 | 72 | 60 | +0.5 | 100 |

| 022.25.500.** | 024.25.500.** | 483 | 477 | 6 | 648 | 105 | 348 | 59 | 60 | +0.5 | 100 | |||||||||||

| 020.20.560.** | 021.20.560.** | 023.20.560.** | 676 | 444 | 106 | 640 | 480 | 20 | 18 | 583 | 577 | 96 | 26 | 4/M10*1 | 5 | 705 | 138 | 415 | 84 | 60 | +0.5 | 115 |

| 022.20.560.** | 024.20.560.** | 543 | 537 | 6 | 708 | 115 | 408 | 69 | 60 | +0.5 | 115 | |||||||||||

| 020.25.630.** | 021.25.630.** | 023.25.630.** | 746 | 514 | 106 | 710 | 550 | 24 | 18 | 653 | 647 | 96 | 26 | 4/M10*1 | 6 | 792 | 129 | 480 | 81 | 60 | +0.5 | 130 |

| 022.25.630.** | 024.25.630.** | 613 | 607 | 8 | 792 | 96 | 472 | 60 | 60 | +0.5 | 130 | |||||||||||

| 020.25.710.** | 021.25.710.** | 023.25.710.** | 826 | 594 | 106 | 790 | 630 | 24 | 18 | 733 | 727 | 96 | 26 | 4/M10*1 | 6 | 864 | 141 | 558 | 94 | 60 | +0.5 | 140 |

| 022.25.710.** | 024.25.710.** | 693 | 687 | 8 | 864 | 105 | 552 | 70 | 60 | +0.5 | 140 | |||||||||||

| 020.30.800.** | 021.30.800.** | 023.30.800.** | 942 | 658 | 124 | 898 | 702 | 30 | 22 | 828 | 822 | 114 | 29 | 6/M10*1 | 8 | 984 | 120 | 616 | 78 | 80 | +0.5 | 200 |

| 022.30.800.** | 024.30.800.** | 778 | 771 | 10 | 990 | 96 | 610 | 62 | 80 | +0.5 | 200 | |||||||||||

| 020.30.900.** | 021.30.900.** | 023.30.900.** | 1042 | 758 | 124 | 998 | 802 | 30 | 22 | 928 | 922 | 114 | 29 | 6/M10*1 | 8 | 1088 | 133 | 712 | 90 | 80 | +0.5 | 250 |

| 022.30.900.** | 024.30.900.** | 878 | 871 | 10 | 1090 | 106 | 710 | 72 | 80 | +0.5 | 250 | |||||||||||

| 020.30.1000.** | 021.30.1000.** | 023.30.1000.** | 1142 | 858 | 124 | 1098 | 902 | 36 | 22 | 1028 | 1022 | 114 | 29 | 6/M10*1 | 10 | 1200 | 117 | 810 | 82 | 80 | +0.5 | 300 |

| 022.30.1000.** | 024.30.1000.** | 978 | 971 | 12 | 1200 | 97 | 792 | 67 | 80 | +0.5 | 300 | |||||||||||

| 020.30.1120.** | 021.30.1120.** | 023.30.1120.** | 1262 | 978 | 124 | 1218 | 1022 | 36 | 22 | 1148 | 1142 | 114 | 29 | 6/M10*1 | 10 | 1320 | 129 | 920 | 93 | 80 | +0.5 | 340 |

| 022.30.1120.** | 024.30.1120.** | 1098 | 1091 | 12 | 1320 | 107 | 912 | 77 | 80 | +0.5 | 340 | |||||||||||

| 020.40.1250.** | 021.40.1250.** | 023.40.1250.** | 1426 | 1074 | 160 | 1374 | 1126 | 40 | 26 | 1286 | 1282 | 150 | 39 | 6/M10*1 | 12 | 1500 | 122 | 1008 | 85 | 90 | +0.5 | 580 |

| 022.40.1250.** | 024.40.1250.** | 1218 | 1214 | 14 | 1498 | 104 | 1008 | 73 | 90 | +0.5 | 580 | |||||||||||

| 020.40.1400.** | 021.40.1400.** | 023.40.1400.** | 1576 | 1224 | 160 | 1524 | 1272 | 40 | 26 | 1436 | 1432 | 150 | 39 | 6/M10*1 | 12 | 1644 | 134 | 1152 | 97 | 90 | +0.5 | 650 |

| 022.40.1400.** | 024.40.1400.** | 1368 | 1364 | 14 | 1652 | 115 | 1148 | 83 | 90 | +0.5 | 650 | |||||||||||

| 020.40.1600.** | 021.40.1600.** | 023.40.1600.** | 1776 | 1424 | 160 | 1724 | 1476 | 45 | 26 | 1636 | 1632 | 150 | 39 | 8/M10*1 | 14 | 1848 | 129 | 1344 | 97 | 90 | +0.5 | 750 |

| 022.40.1600.** | 024.40.1600.** | 1568 | 1564 | 16 | 1856 | 113 | 1344 | 85 | 90 | +0.5 | 750 | |||||||||||

| 020.40.1800.** | 021.40.1800.** | 023.40.1800.** | 1976 | 1624 | 160 | 1924 | 1676 | 45 | 26 | 1836 | 1832 | 150 | 39 | 8/M10*1 | 14 | 2058 | 144 | 1540 | 111 | 90 | +0.5 | 820 |

| 022.40.1800.** | 024.40.1800.** | 1768 | 1764 | 16 | 2064 | 126 | 1536 | 97 | 90 | +0.5 | 820 | |||||||||||

| 020.50.2000.** | 021.50.2000.** | 023.50.2000.** | 2215 | 1785 | 190 | 2149 | 1851 | 48 | 33 | 2038 | 2032 | 178 | 47 | 8/M10*1 | 16 | 2304 | 141 | 1696 | 107 | 120 | +0.5 | 1150 |

| 022.50.2000.** | 024.50.2000.** | 1968 | 1962 | 18 | 2304 | 125 | 1692 | 95 | 120 | +0.5 | 1150 | |||||||||||

| 020.50.2240.** | 021.50.2240.** | 023.50.2240.** | 2455 | 2025 | 190 | 2389 | 2091 | 48 | 33 | 2278 | 2272 | 178 | 47 | 8/M10*1 | 16 | 2544 | 156 | 1936 | 122 | 120 | +0.5 | 1500 |

| 022.50.2240.** | 024.50.2240.** | 2208 | 2202 | 18 | 2556 | 139 | 1926 | 108 | 120 | +0.5 | 1500 | |||||||||||

| 020.50.2500.** | 021.50.2500.** | 023.50.2500.** | 2715 | 2285 | 190 | 2649 | 2351 | 56 | 33 | 2538 | 2532 | 178 | 47 | 8/M10*1 | 18 | 2804 | 153 | 2196 | 123 | 120 | +0.5 | 1500 |

| 022.50.2500.** | 024.50.2500.** | 2468 | 2462 | 20 | 2820 | 138 | 2180 | 110 | 120 | +0.5 | 1500 | |||||||||||

| 020.50.2800.** | 021.50.2800.** | 023.50.2800.** | 3015 | 2585 | 190 | 2949 | 2651 | 56 | 33 | 2838 | 2832 | 178 | 47 | 8/M10*1 | 18 | 3114 | 170 | 2484 | 139 | 120 | +0.5 | 1900 |

| 022.50.2800.** | 024.50.2800.** | 2768 | 2762 | 20 | 3120 | 153 | 2480 | 125 | 120 | +0.5 | 1900 | |||||||||||

| 020.60.3150.** | 021.60.3150.** | 023.60.3150.** | 3428 | 2872 | 226 | 3338 | 2962 | 56 | 45 | 3198 | 3192 | 214 | 56 | 8/M10*1 | 20 | 3540 | 174 | 2760 | 139 | 150 | +0.5 | 3300 |

| 022.60.3150.** | 024.60.3150.** | 3108 | 3102 | 22 | 3542 | 158 | 2750 | 126 | 150 | +0.5 | 3300 | |||||||||||

| 020.60.3550.** | 021.60.3550.** | 023.60.3550.** | 3828 | 3272 | 226 | 3738 | 3362 | 56 | 45 | 3598 | 3592 | 214 | 56 | 8/M10*1 | 20 | 3940 | 194 | 3160 | 159 | 150 | +0.5 | 3700 |

| 022.60.3550.** | 024.60.3550.** | 3508 | 3502 | 22 | 3938 | 176 | 3168 | 145 | 150 | +0.5 | 3700 | |||||||||||

| 020.60.4000.** | 021.60.4000.** | 023.60.4000.** | 4278 | 3722 | 226 | 4188 | 3812 | 60 | 45 | 4048 | 4042 | 214 | 56 | 10/M10*1 | 22 | 4400 | 197 | 3608 | 165 | 150 | +0.5 | 4200 |

| 022.60.4000.** | 024.60.4000.** | 3958 | 3952 | 25 | 4400 | 173 | 3600 | 145 | 150 | +0.5 | 4200 | |||||||||||

| 020.60.4500.** | 021.60.4500.** | 023.60.4500.** | 4778 | 4222 | 226 | 4688 | 4312 | 60 | 45 | 4548 | 4542 | 214 | 56 | 10/M10*1 | 22 | 4884 | 219 | 4114 | 188 | 150 | +0.5 | 4700 |

| 022.60.4500.** | 024.60.4500.** | 4458 | 4452 | 25 | 4900 | 193 | 4100 | 165 | 150 | +0.5 | 4700 | |||||||||||