slewing bearing

-

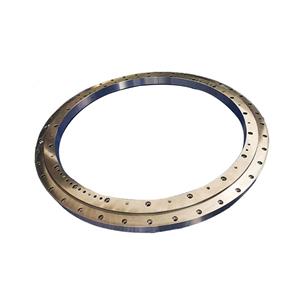

High Precision Low Noise Slew Bearing For CT Scanner Machine

Slew Bearing For CT Scanner Machine is featured with high precision, high speed and low noise. Firstly, the 42CrMo quenched and tempered material is used to make the material performance better and more stable, which guarantees the product quality from the source; Secondly, the product raceway and appearance are comprehensively polished to ensure high product precision; Thirdly, for the product's silent requirements, a special segmented nylon cage device is used to lock the ball in the cage pocket while ensuring that the steel ball can rotate freely, thereby reducing the noise impact caused by the free movement of the cage in the raceway. Reduce rotating noise. Through the above efforts, we ensure that the finished products of the slewing ring meet various technical requirements.

Email Details -

Yaw Bearing For Wind Turbine Generator

The wind turbine yaw bearing is installed at the connection between the tower and the cockpit, and the pitch bearing is installed at the connection between the root of each blade and the hub. Each wind turbine uses one set of yaw bearing and three sets of pitch bearing. The material of the yaw and pitch bearing rings is 42CrMo, the heat treatment adopts the overall quenching and tempering treatment, and the surface of the raceway is quenched. The force of yaw and pitch bearings is complex, and the impact and vibration are relatively large. Therefore, the bearing is required to withstand both impact and large load. The life of the wind turbine main engine requires 20 years, and the cost of bearing installation is relatively large, so the life of the yaw and pitch bearings is required to reach 20 years. The hardness of the bearing ring base is 240-280HB, which can withstand impact without plastic deformation. At the same time, the surface quenching hardness of the raceway reaches 55-62HRC, which can increase the contact fatigue life and ensure the service life of the bearing.

yaw bearing wind turbine slewing bearing Main shaft bearing for wind turbine ball bearing slewing ringEmail Details -

Palletizing Robot Slewing Bearing

Palletizing robot require flexible operation, accurate point position, light and fast, so they are generally used in light and precision slewing bearings. Our company has a professional production line of this kind of product, specializing in the production of such high-precision rotary bearing, which is one of our company’s main product series. Small slewing bearing, as a key accessory of industrial robot, is an indispensable part of it. At present, from the perspective of the development trend of robots, modern robots are developing in the direction of lighter weight, precision and intelligence, which requires the supporting slewing bearing to have a lighter structure and more advanced manufacturing and assembly processes. Usually, The installation space of the industrial robot slewing bearing is very limited, and the slewing bearing must meet the performance requirements of the robot host for the bearing capacity, stiffness, precision and friction torque of the slewing bearing in the limited installation space. It is difficult to meet this requirement by selecting standard slewing bearings, and light slewing bearings can solve this problem well. This kind of slewing bearing has the characteristics of small diameter and large number of steel balls, and can bear radial load, bidirectional axial load and overturning moment.

robot slewing bearing precision slewing bearing light series slewing bearing slew bearing for stacker reclaimerEmail Details -

Swing Bearing For Volvo

Excavator is one of the important equipment in modern engineering construction. The reason why the excavator can turn left and right in the work is because of the slewing mechanism, which is one of the important components of the hydraulic excavator. The slewing mechanism is connected with the traveling device through a slewing bearing, and the slewing drive device makes the platform rotate relative to the traveling device, and drives the working device to rotate around its central axis of rotation. We are specialized in the production of engineering machinery slewing bearings, drive shafts and matched pinions. For some common model excavators slewing bearing, we have ready stock and can deliver within one week. Our company has a special quality testing laboratory, devoted to product design and development, product application and testing methods. At the same time, the company also has advanced production equipment and testing equipment to ensure that products have high performance, long life, low friction, high precision.

Email Details -

Hot

Swing Bearing For Liebherr

Excavator is one of the important equipment in modern engineering construction. The reason why the excavator can turn left and right in the work is because of the slewing mechanism, which is one of the important components of the hydraulic excavator. The slewing mechanism is connected with the traveling device through a slewing bearing, and the slewing drive device makes the platform rotate relative to the traveling device, and drives the working device to rotate around its central axis of rotation. We are specialized in the production of engineering machinery slewing bearings, drive shafts and matched pinions. For some common model excavators slewing bearing, we have ready stock and can deliver within one week. Our company has a special quality testing laboratory, devoted to product design and development, product application and testing methods. At the same time, the company also has advanced production equipment and testing equipment to ensure that products have high performance, long life, low friction, high precision.

Email Details -

Swing Bearing For Doosan

Slewing bearing is a new type of slewing product, which can bear large axial load, radial load and overturning moment and other comprehensive loads at the same time. Construction machinery is the initial application of slewing bearings, and it is also most widely used. We are specialized in the production of engineering machinery slewing bearings, drive shafts and matched pinions. For some common model excavators slewing bearing, we have ready stock and can deliver within one week. Our company has a special quality testing laboratory, devoted to product design and development, product application and testing methods. At the same time, the company also has advanced production equipment and testing equipment to ensure that products have high performance, long life, low friction, high precision.

Email Details