Slewing Bearing For Ship Crane

- LYHGB

- Luoyang

- 45 days

- 1000 sets/ month

Crane also is known as marine crane, is a large deck machinery on the ship. It is a kind of equipment for loading and unloading cargo on the ship. Hydraulic crane is a kind of equipment for loading and unloading cargo commonly used on the ship. Generally including portal crane, ship unloader, floating crane, etc., commonly used single row four-point ball slewing ring bearing, three rows roller slewing bearing and double row ball slewing ring bearing. These are our regular products, but also our company’s main advantage products.

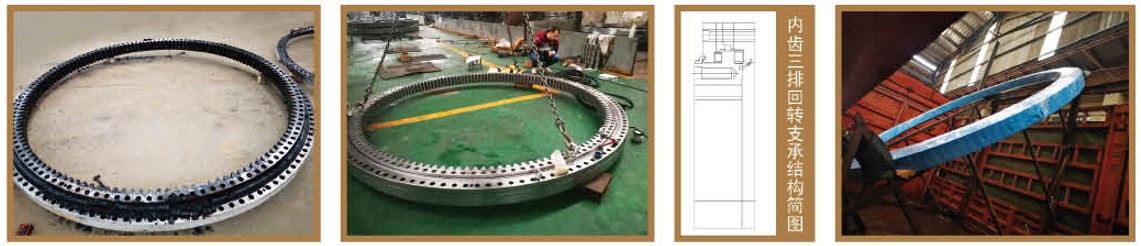

Among them, Three row roller slewing bearing is the most commonly used one.Three row roller slewing bearing can bear different loads simultaneously. The capacity load is the largest one comparing with other types of slewing bearing. Due to the large dimension and solid structure, it is especially suitable for heavy-duty machineries, such as port crane, ship crane, etc.

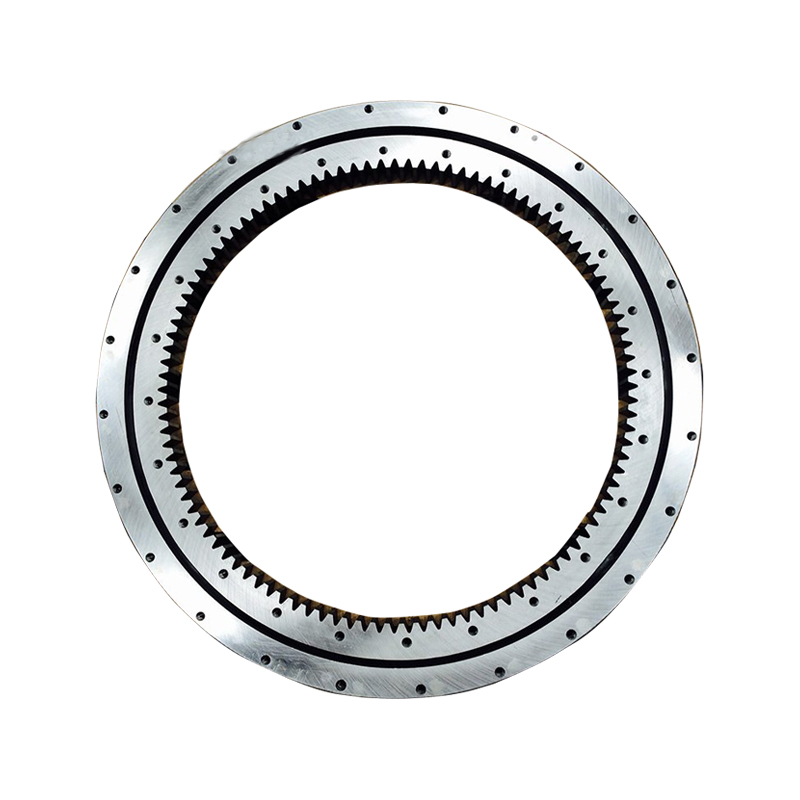

At present, our company often provides four-point ball slewing bearing with inner teeth and double row ball slewing bearing with different ball diameters. Generally, we need to provide CCS, ABS, DNV and other classification societies certification. The other is the maintenance and replacement of slewing bearings for cranes on board ships, such as Mitsubishi crane, TSUJI and other brand cranes.

The commonly repaired and replaced models are 013.50.2877 (figure number: ASB-A0057) 023.60.2890 (figure number: 12-MNR1394.87/53), 013.50.2875 (figure number: 62-MNR2850.87/53).

This series of slewing bearings is one of our main competitive products.

Slewing Bearing For Ship Crane

Crane also is known as marine crane, is a large deck machinery on the ship. It is a kind of equipment for loading and unloading cargo on the ship. Hydraulic crane is a kind of equipment for loading and unloading cargo commonly used on the ship. Generally including portal crane, ship unloader, floating crane, etc., commonly used single row four-point ball slewing ring bearing, three rows roller slewing bearing and double row ball slewing ring bearing. These are our regular products, but also our company’s main advantage products.

Among them, Three row roller slewing bearing is the most commonly used one.Three row roller slewing bearing can bear different loads simultaneously. The capacity load is the largest one comparing with other types of slewing bearing. Due to the large dimension and solid structure, it is especially suitable for heavy-duty machineries, such as port crane, ship crane, etc.

At present, our company often provides four-point ball slewing bearing with inner teeth and double row ball slewing bearing with different ball diameters. Generally, we need to provide CCS, ABS, DNV and other classification societies certification. The other is the maintenance and replacement of slewing bearings for cranes on board ships, such as Mitsubishi crane, TSUJI and other brand cranes.

The commonly repaired and replaced models are 013.50.2877 (figure number: ASB-A0057) 023.60.2890 (figure number: 12-MNR1394.87/53), 013.50.2875 (figure number: 62-MNR2850.87/53).

This series of slewing bearings is one of our main competitive products.

Cases

1. Survey and reproduction of the Russian ship crane’s old slewing bearing

At the beginning of 2021, we undertook an order for the surveying and reproduction of a Crane slewing bearing from a ship management company in Jiangsu. Due to the age of this ship, the owner could not find drawings of the bearing, so the old bearing was taken down and sent back to our factory for surveying and reproduction. After surveying and mapping, the old crane slewing bearing was a three-row roller structure with internal teeth. Our company surveyed and mapped the physical drawing of the old bearing and arranged production in time, and completed it within 30 days. Also per requirements of the owner, we carried out Russian ship inspection work. And then the product was delivered to a shipyard in Zhou Shan at the first time. The installation and commissioning were very successful finally. The ship-owner can set sail again and turn on the wealth journey!

2. Survey and reproduction of the slewing bearing of a crane in Shanghai dockside

In mid-2020, our company received a call from a ship management company in Shanghai. They had bought an old ship and four cranes on it were planned to be converted into shore cranes. The original slewing bearings on the cranes need to be replaced. Due to the long time age, the owner did not find the slewing ring drawing, so he sent the old bearing to our factory for surveying and re-production. This bearing is a double-row ball type slewing bearing with internal teeth. After tightly scheduled production, our company sent the new slewing bearing to the owner’s installation site in time, and instructed for successful commissioning. It has been successfully put into operation now.

3. Crane slewing bearing replacement according to the Singapore shipping-owner’s drawing

In the middle year of 2021, there was a problem with the slewing bearing of a crane on a ship in Singapore and the slewing bearing needs replacement urgently, meanwhile the ship was docked in Singapore to unload cargo. Being introduced by people, the ship-owner came to us and provided the drawing to us. It is an internal gear single row slewing bearing. The ship will discharge cargo at Qingdao, China this month, so it is time to replace the old slewing bearing. We arranged production immediately after get the order, and complete the production within 25 days. Then new slewing bearing and fixing bolts were sent to the installation site of a shipyard in Zhou Shan at the first time, also we arranged our technical personnel to guide the installation on site, The slewing bearing was successfully installed in time, and the next day the ship owner set sail. The ship owner returned with full load and started the journey of wealth.