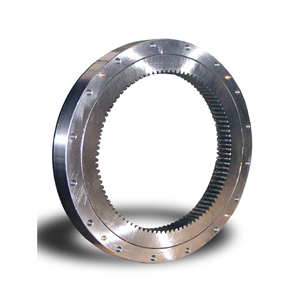

crane slewing bearing

-

High technology high quality customizable slewing rotary bearings

1.The three row roller type rotary bearing has three seat rings, with the upper, lower, and radial raceways separated, and the load of each row of rollers can be accurately determined 2.Capable of withstanding various loads simultaneously, with large axial and radial dimensions and a sturdy structure

Email Details -

Carrying large customizable heavy duty machinery slewing bearings

The single-row crossed roller slewing bearing is composed of two seat rings. It has a compact structure, light weight, high manufacturing precision, small assembly clearance, and high requirements for installation accuracy. The rollers are arranged in a 1:1 cross and can bear the bearings at the same time. It has axial force, overturning moment and large radial force, and is widely used in lifting, transportation and engineering machinery products.

Email Details -

high quality customizable construction machinery slewing bearings

The single-row four-point contact ball slewing bearing is composed of two seat rings. It has a compact structure and light weight. The steel balls are in four-point contact with the arc raceway and can withstand axial force, radial force and overturning moment at the same time. Construction machinery such as rotary conveyors, welding operators, small and medium-sized cranes and excavators can all be used.

high quality slewing bearings construction machinery slewing bearings single row four point contact ball slewing bearing Slewing bearing manufacturerEmail Details -

Single Row Four Point Contact Ball Slewing Bearing( 01 Series)

Single row four point contact ball slewing bearing 01 series is a standard model series in China. It is made of two seat rings. The balls and the raceway are with four points contact, via which the axial force, radial force and resultant moment is born simultaneously. Outer Diameter is from 280mm to 4726mm. Most models slewing ring are with ready stock or semi-finished material stock, which can deliver out within 15 days. Standard material we adopt is 50Mn and 42CrMo. Other customized material is also acceptable. We support models selection based on your application; teeth quenching and grinding; customized surface treatment like Blackening, phosphating, galvanizing, sandblasting and etc. In the production process of slewing ring bearing, whole process inspection is implemented strictly to ensure that each set of products are qualified. For high-precision products, precise grinding is used to effectively control the parameters of ring ellipse, wall thickness and flatness, so as to ensure that the precision of finished products meets the requirements of standards or customer drawings. This series models are with advantage of compact design, flexible rotating and light weight. It is widely used on rotary conveyor, welding arm and positioner, light/medium duty cranes, excavators and other engineering machines. Please feel free to tell us the application you use and we can help you choose the proper model and offer you a professional solution as soon as possible.

slewing bearing slew bearing with external gear truck crane slewing bearing tower crane slewing bearingEmail Details -

Pitch Bearing Of Wind Turbine Generator

The material pitch bearing rings is 42CrMo, the heat treatment adopts the overall quenching and tempering treatment, and the surface of the raceway is quenched. The force of pitch bearings is complex, and the impact and vibration are relatively large. Therefore, the bearing is required to withstand both impact and large load. The life of the wind turbine main engine is required to be 20 years, and the cost of bearing installation is relatively large, so the life of the yaw and pitch bearings is required to reach 20 years. The hardness of the bearing ring base is 240-280HB, which can withstand impact without plastic deformation. At the same time, the surface quenching hardness of the raceway reaches 55-62HRC, which can increase the contact fatigue life and ensure the service life of the bearing.

Email Details -

High Performance Slewing Bearing For Crane

Slewing bearing is an important "joint" of the crane. Various loads and moments on the working device need to be transmitted to the chassis through the slewing bearing. Because the slewing bearing is overloaded, it is also the part where the crane is prone to failure, so it is necessary to install a new slewing bearing after long-term use. Truck cranes, crawler cranes and other heavy construction cranes are usually using large single row four-point contact ball slewing ring bearing. This type of slewing bearing can bear larger axial load, radial load and tilting moment, enabling crane to lift heavy loads stably and reliably. To improve the manufacturing accuracy and working life of the slewing bearing, we focus on the heat treatment process, raceway quenching to prevent quenching cracks on the surface of the raceway. For high precision products, precise grinding is used to effectively control the parameters of ring ellipse, wall thickness and flatness, so as to ensure that the precision of finished products meets the requirements of standards or customer drawings. So our slewing bearings are with features of high precision, long working life and durable to use.

Email Details -

Slewing Bearing For Ship Crane

Crane also is known as marine crane, is a large deck machinery on the ship. It is a kind of equipment for loading and unloading cargo on the ship. Hydraulic crane is a kind of equipment for loading and unloading cargo commonly used on the ship. Generally including portal crane, ship unloader, floating crane, etc., commonly used single row four-point ball slewing ring bearing, three rows roller slewing bearing and double row ball slewing ring bearing. These are our regular products, but also our company’s main advantage products. Among them, Three row roller slewing bearing is the most commonly used one.Three row roller slewing bearing can bear different loads simultaneously. The capacity load is the largest one comparing with other types of slewing bearing. Due to the large dimension and solid structure, it is especially suitable for heavy-duty machineries, such as port crane, ship crane, etc. At present, our company often provides four-point ball slewing bearing with inner teeth and double row ball slewing bearing with different ball diameters. Generally, we need to provide CCS, ABS, DNV and other classification societies certification. The other is the maintenance and replacement of slewing bearings for cranes on board ships, such as Mitsubishi crane, TSUJI and other brand cranes. The commonly repaired and replaced models are 013.50.2877 (figure number: ASB-A0057) 023.60.2890 (figure number: 12-MNR1394.87/53), 013.50.2875 (figure number: 62-MNR2850.87/53). This series of slewing bearings is one of our main competitive products.

marine crane slewing bearing shipyard crane slewing bearing ship crane slewing bearing offshore crane slewing bearingEmail Details -

Single Row Four Point Contact Ball Swing Bearing( HS Series)

Single row four point contact ball slewing ring HS series is a standard model series in China. It is made of inner ring and outer ring. The rolling balls are four point contact with the raceway. It can bear axial force, radial force and overturning moment at the same time. Outer Diameter is from 725mm to 4860mm. It is with non gear type, internal gear type and external gear type.Standard material we adopt is 50Mn and 42CrMo. Other customized material is also acceptable. We support models selection based on your application; teeth quenching and grinding; customized surface treatment like Blackening, phosphating, galvanizing, sandblasting and etc. In the production process of slewing ring bearing, whole process inspection is implemented strictly to ensure that each set of products are qualified. For high-precision products, precise grinding is used to effectively control the parameters of ring ellipse, wall thickness and flatness, so as to ensure that the precision of finished products meets the requirements of standards or customer drawings. This series models are with advantage of compact design, flexible rotating and light weight. It is widely used on rotary conveyor, welding arm and positioner, light/medium duty cranes, excavators and other engineering machines. Please feel free to tell us the application you use and we can help you choose the proper model and offer you a professional solution as soon as possible.

Email Details