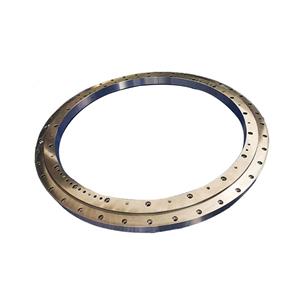

slewing ring

-

Ball And Roller Combination Slewing Bearing

Ball and Roller Combination Slewing Bearing is mainly composed of an outer ring, an inner ring, rollers and steel balls. The inner ring and the outer ring each have a horizontal linear raceway and a spherical raceway, and the rollers are located in the horizontal In the linear raceway, the steel balls are located in the spherical raceway. The horizontally placed rollers bear the axial force, the radial force is borne by the steel ball, and the tilting moment is jointly borne by the both. It can not only bear large axial force, but also bear certain tilting moment and radial force, and has a small sectional size. This type of product is mainly used in construction machinery and equipment such as stackers and reclaimers.

Email Details -

Swing Bearing For Komatsu

Slewing ring bearing is widely used in excavator equipment. It belongs to wear parts. We are specialized in the production of engineering machinery slewing bearings, drive shafts and other gear parts. If you only need the bearing parts like steel balls, rollers, cages, it is also available. For some common model excavators’slewing bearing, we have ready stock and can deliver within one week. PC200, PC220, PC300 is our hot selling models and also the drive gear shaft. If you have old slewing bearing in hand, we can instruct you to measure the detailed size to make a professional drawing and then manufacture it for you.

Email Details -

High Efficient Slewing Bearing For Stacker Reclaimer

Bucket wheel machine, also known as bucket wheel stacker and reclaimer, is an efficient equipment for continuous loading and unloading of bulk bulk materials in modern industries. It has been widely used in ports, wharfs, metallurgy, cement, steel plants, coking plants, coal storage plants, power plants, etc. The stacking operation of bulk material (ore, coal, coke, sand and gravel) storage yard. The function of the slewing bearing of the bucket wheel stacker and reclaimer is to support the slewing structure, bear the vertical direction force, horizontal force and tilting moment generated by the slewing structure during operation and non-operation, so that the machine is in a stable state. In view of its working conditions, there are two commonly used slewing bearing structures, one is a heavy-duty external tooth single-row cross-roller slewing bearing, such as 1797/2100, 1797/2460, 1797/2500, 1797/2600, 1797/2635 , 1797/3230, etc.; the other is a three-row roller slewing bearing with external teeth, such as 131/132.45.2500, 131/132.45.2800, 131/132.50.3150, 131/132.50.3550, 131/132.50.4000 , 131/132.50.4500, etc. These are the models that our company often makes. For detailed information, please call for consultation. If non-standard customization is required, our company can provide technical support such as selection, design, calculation, etc., you can call for details.

slew bearing for stacker reclaimer stacker slew bearing slewing ring for stacker reclaimer large diameter thin bearingsEmail Details -

Heavy Duty Slewing Bearing For Port Crane Equipment

Port hoisting machinery generally includes portal cranes, ship unloaders, floating cranes, etc., commonly used single-row four-point ball type, three-row roller type and double-row ball type slewing ring bearings. Port cranes usually use three-row roller slewing bearings with internal or external teeth with a diameter of 4 meters to withstand high overturning moments. Our company often provides slewing bearings in this field, such as single-row ball type, 011/012.60.2000, 011/012.60.2240, 011/012.60.2500, 011/012.60.2800, 011/012.60.3150, etc., three-row roller type, etc. Slewing bearings include 131/132.45.2500, 131/132.45.2800, 131/132.50.3150, 131/132.50.3550, 131/132.50.4000, 131/132.50.4500, etc., as well as double-row ball slewing bearings 021/022.50 .2500, 021/022.50.2800, etc., are our main advantage products. If non-standard customization is required, our company can provide technical support such as selection, design, calculation, etc., you can call for details.

Email Details -

Hot

High Load Slewing Bearing For Ladle Turret

Ladle turret is commonly known as continuous casting machine. Slewing bearing for ladle turret generally uses three row roller structure slewing bearing, such as 132.45.2500/2800/3150/3550, etc. This structural product is a slewing bearing with high bearing capacity. , mainly used in heavy duty work situations. It consists of three ferrules, the upper and lower rows of rollers are distributed horizontally, and the radial force is borne by the three rows of rollers arranged vertically, so it can withstand the axial force and tilting moment from two directions. The ladle turntable is the key equipment of the continuous casting machine. It is used to carry and support the ladle for pouring. It is usually set between the molten steel receiving span and the column row of the pouring span. The designed ladle rotation radius makes the ladle nozzle at the specified position above the tundish when pouring steel. The ladle is placed on the turntable by the crane on the side of the molten steel receiving span, and is rotated by the turntable to make the ladle stop above the tundish to supply its molten steel. The poured empty package is rotated through the turntable, and then transported back to the molten steel receiving span. The load-bearing capacity and safety performance of the product are required to be high, so the three-row roller structure slewing bearing is often used. If non-standard customization is required, our company can provide technical support such as selection, design, calculation, etc., you can call for details.

Email Details -

Three Row Roller Slewing Bearing

Three-row roller slewing bearing has three seat rings, the upper and lower raceways and the radial raceways are separated. The upper and lower rows of rollers are arranged horizontally, and the middle row of rollers is arranged vertically. It can be made into an inner gear ring or an outer gear ring according to the equipment structure and work needs. The axial force and tilting moment in the two directions are borne by the upper and lower horizontal rollers, and the radial force is borne by the vertically arranged third row of rollers. According to the different characteristics of the load, the upper and lower rows of rollers can be of the same diameter or of different diameters. So that the load of each row of roller can be determined accurately. Being able to bear all kinds of loads at the same time, it is the largest one of the four structural products with large axial and radial dimensions and firm structure. It is especially suitable for heavy machinery requiring larger diameter, such as bucket wheel stacker and declaimer, wheel crane, marine crane, port crane, ladle turret and large tonnage truck crane, heavy machinery and so on.

Email Details -

Slewing Bearing For Ferris Wheel

In amusement equipment, slewing bearings are used in Ferris wheels, large pendulums, and flying chairs. Broadly speaking, a slewing bearing is a large bearing that can withstand comprehensive loads, and can bear large axial, radial loads and overturning moments at the same time. Slewing bearings generally have mounting holes, internal gears or external gears, lubricating oil holes and sealing devices, so that the design of the main engine can be compact, easy to guide, and easy to maintain. Ferris wheel usually adopts double row ball slewing bearing. There are two rows of rolling elements, which can bear large axial load, radial load and tilting moment. It rotates flexibly and stably with higher safety factor. For some large ferris wheel, four contact ball slewing bearing is selected too, outer dia is about 4100mm, depth 85mm. Slewing ring bearings used on Ferris/Sky wheels are used with inner rings. In most cases, the bearing should be light enough and safe enough to rotate. The slewing ring bearings used on the Ferris wheel/sky wheel generally require a long service time, so it is also very important for anti-corrosion. If non-standard customization is required, our company can provide technical support such as selection, design, calculation, etc.

Email Details -

Single Row Four Point Contact Ball Slewing Ring( Q Series)

Single row four point contact ball slewing ring Q series is a standard model series in China. Q means single row ball type. QW is external gear type, QN is internal gear type, QU is non gear type. It is made of two seat rings. The balls and the raceway are with four points contact, via which the axial force, radial force and resultant moment is born simultaneously. Outer Diameter is from 360 mm to 4700mm. Standard material we adopt is 50Mn and 42CrMo. Other customized material is also acceptable. We support models selection based on your application; teeth quenching and grinding; customized surface treatment like Blackening, phosphating, galvanizing, sandblasting and etc. In the production process of slewing ring bearing, whole process inspection is implemented strictly to ensure that each set of products are qualified. For high-precision products, precise grinding is used to effectively control the parameters of ring ellipse, wall thickness and flatness, so as to ensure that the precision of finished products meets the requirements of standards or customer drawings. This series models are with advantage of compact design, flexible rotating and light weight. It is widely used on rotary conveyor, welding arm and positioner, light/medium duty cranes, excavators and other engineering machines. Please feel free to tell us the application you use and we can help you choose the proper model and offer you a professional solution as soon as possible.

Email Details -

High Precision Low Noise Slew Bearing For CT Scanner Machine

Slew Bearing For CT Scanner Machine is featured with high precision, high speed and low noise. Firstly, the 42CrMo quenched and tempered material is used to make the material performance better and more stable, which guarantees the product quality from the source; Secondly, the product raceway and appearance are comprehensively polished to ensure high product precision; Thirdly, for the product's silent requirements, a special segmented nylon cage device is used to lock the ball in the cage pocket while ensuring that the steel ball can rotate freely, thereby reducing the noise impact caused by the free movement of the cage in the raceway. Reduce rotating noise. Through the above efforts, we ensure that the finished products of the slewing ring meet various technical requirements.

Email Details