Three Row Roller Slewing Bearing

- LYHGB

- Luoyang

- 45 days

- 4000 sets/ month

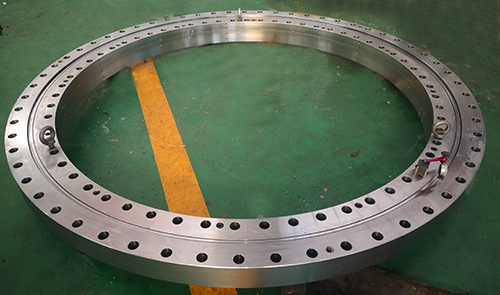

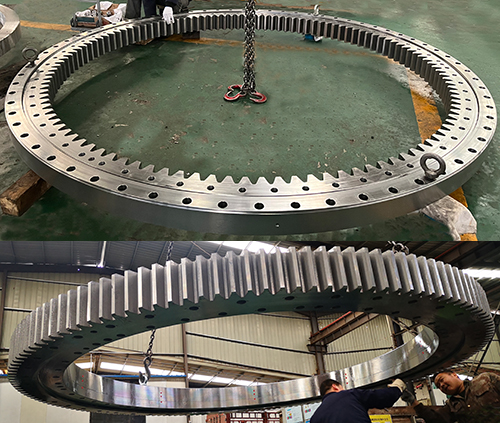

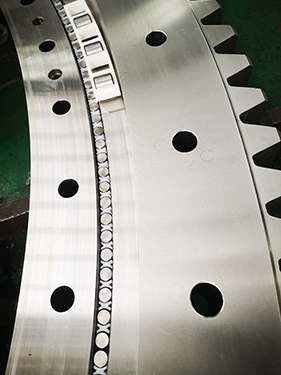

Three-row roller slewing bearing has three seat rings, the upper and lower raceways and the radial raceways are separated. The upper and lower rows of rollers are arranged horizontally, and the middle row of rollers is arranged vertically. It can be made into an inner gear ring or an outer gear ring according to the equipment structure and work needs. The axial force and tilting moment in the two directions are borne by the upper and lower horizontal rollers, and the radial force is borne by the vertically arranged third row of rollers. According to the different characteristics of the load, the upper and lower rows of rollers can be of the same diameter or of different diameters. So that the load of each row of roller can be determined accurately. Being able to bear all kinds of loads at the same time, it is the largest one of the four structural products with large axial and radial dimensions and firm structure. It is especially suitable for heavy machinery requiring larger diameter, such as bucket wheel stacker and declaimer, wheel crane, marine crane, port crane, ladle turret and large tonnage truck crane, heavy machinery and so on.

Three row roller slewing bearing

Three-row roller slewing bearing has three seat rings, the upper and lower raceways and the radial raceways are separated. The upper and lower rows of rollers are arranged horizontally, and the middle row of rollers is arranged vertically. It can be made into an inner gear ring or an outer gear ring according to the equipment structure and work needs. The axial force and tilting moment in the two directions are borne by the upper and lower horizontal rollers, and the radial force is borne by the vertically arranged third row of rollers. According to the different characteristics of the load, the upper and lower rows of rollers can be of the same diameter or of different diameters. So that the load of each row of roller can be determined accurately. Being able to bear all kinds of loads at the same time, it is the largest one of the four structural products with large axial and radial dimensions and firm structure.

Application

It is especially suitable for heavy machinery requiring larger diameter, such as

bucket wheel stacker and declaimer,

wheel crane,

marine crane,

port crane,

ladle turret,

large tonnage truck crane,

heavy machinery and so on

Features

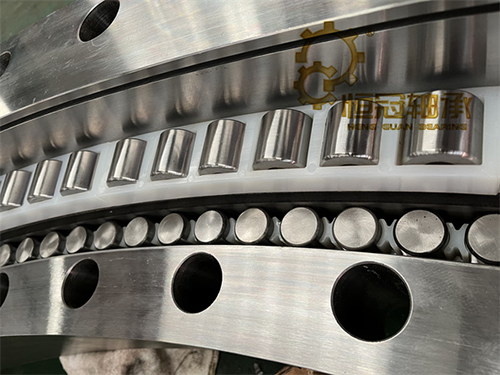

1. Compared with the cross-roller bearing, under the same bearing diameter, the number of rolling elements (contact points) is increased, thereby reducing the load on each rolling element; After the contact is changed to line contact, the contact stress can be reduced and the bearing capacity can be improved.

2. Since the radial force and the axial force are borne by the two rows of rollers respectively, the direction of the reaction force is consistent with the main direction of the load on the bearing, so the contact load between the rollers and the raceway can be reduced.

3. Under the same load, it has smaller dimensions, smaller section and lighter weight than other types of supports, which can save materials and reduce material costs.

4. The raceway of the rolling ring is a plane and a cylindrical surface, which is more convenient to process.

5. In addition to bearing radial force, the vertical roller also has the guiding function of bearing the tilting moment.

Technical Parameters

| Bearing type | Boundary dimensions | Mounting hole diameter | Structure dimensions | Gear parameters | Mass KG | |||||||||||||||||

| Non-gear type | External gear type | Internal gear type | D | d | H | D1 | D2 | n | φ | D3 | d1 | h1 | h2 | n3 | m | Ext gear | Int gear | b | x | |||

| mm | mm | mm | mm | Da | Z | da | Z | mm | ||||||||||||||

| 130.25.500.** | 131.25.500.** | 133.25.500.** | 634 | 366 | 148 | 598 | 402 | 24 | 18 | 537 | 526 | 32 | 10 | 2X4/M10X1 | 5 | 665 | 130 | 335 | 68 | 80 | +0.5 | 224 |

| 132.25.500.** | 134.25.500.** | 474 | 463 | 32 | 10 | 2X4/M10X1 | 6 | 666 | 108 | 336 | 57 | 80 | +0.5 | 224 | ||||||||

| 130.25.560.** | 131.25.560.** | 133.25.560.** | 694 | 426 | 148 | 658 | 462 | 24 | 18 | 597 | 586 | 32 | 10 | 2X4/M10X1 | 5 | 725 | 142 | 395 | 80 | 80 | +0.5 | 240 |

| 132.25.560.** | 134.25.560.** | 534 | 523 | 32 | 10 | 2X4/M10X1 | 6 | 726 | 118 | 396 | 67 | 80 | +0.5 | 240 | ||||||||

| 130.25.630.** | 131.25.630.** | 133.25.630.** | 764 | 496 | 148 | 728 | 532 | 28 | 18 | 667 | 656 | 32 | 10 | 2X4/M10X1 | 6 | 810 | 132 | 456 | 77 | 80 | +0.5 | 270 |

| 132.25.630.** | 134.25.630.** | 604 | 593 | 32 | 10 | 2X4/M10X1 | 8 | 808 | 98 | 456 | 58 | 80 | +0.5 | 270 | ||||||||

| 130.25.710.** | 131.25.710.** | 133.25.710.** | 844 | 576 | 148 | 808 | 612 | 28 | 18 | 747 | 736 | 32 | 10 | 2X4/M10X1 | 6 | 888 | 145 | 534 | 90 | 80 | +0.5 | 300 |

| 132.25.710.** | 134.25.710.** | 684 | 673 | 32 | 10 | 2X4/M10X1 | 8 | 888 | 108 | 536 | 68 | 80 | +0.5 | 300 | ||||||||

| 130.32.800.** | 131.32.800.** | 133.32.800.** | 964 | 636 | 182 | 920 | 680 | 36 | 22 | 841 | 830 | 32 | 10 | 2X4/M10X1 | 8 | 1008 | 123 | 592 | 75 | 120 | +0.5 | 500 |

| 132.32.800.** | 134.32.800.** | 770 | 759 | 40 | 10 | 2X4/M10X1 | 10 | 1010 | 98 | 590 | 60 | 120 | +0.5 | 500 | ||||||||

| 130.32.900.** | 131.32.900.** | 133.32.900.** | 1064 | 736 | 182 | 1020 | 780 | 36 | 22 | 941 | 930 | 40 | 10 | 2X4/M10X1 | 8 | 1104 | 135 | 688 | 87 | 120 | +0.5 | 600 |

| 132.32.900.** | 134.32.900.** | 870 | 859 | 40 | 10 | 2X5/M10X1 | 10 | 1110 | 108 | 690 | 70 | 120 | +0.5 | 600 | ||||||||

| 130.32.1000.** | 131.32.1000.** | 133.32.1000.** | 1164 | 836 | 182 | 1120 | 880 | 40 | 22 | 1041 | 1030 | 40 | 10 | 2X5/M10X1 | 10 | 1220 | 119 | 780 | 79 | 120 | +0.5 | 680 |

| 132.32.1000.** | 134.32.1000.** | 970 | 959 | 40 | 10 | 2X5/M10X1 | 12 | 1224 | 99 | 780 | 66 | 120 | +0.5 | 680 | ||||||||

| 130.32.1120.** | 131.32.1120.** | 133.32.1120.** | 1284 | 956 | 182 | 1240 | 1000 | 40 | 22 | 1161 | 1150 | 40 | 10 | 2X5/M10X1 | 10 | 1340 | 131 | 900 | 91 | 120 | +0.5 | 820 |

| 132.32.1120.** | 134.32.1120.** | 1090 | 1079 | 40 | 10 | 2X5/M10X1 | 12 | 1344 | 109 | 900 | 76 | 120 | +0.5 | 820 | ||||||||

| 130.40.1250.** | 131.40.1250.** | 133.40.1250.** | 1445 | 1055 | 220 | 1393 | 1107 | 45 | 26 | 1300 | 1290 | 50 | 10 | 2X5/M10X1 | 12 | 1512 | 123 | 984 | 83 | 150 | +0.5 | 1200 |

| 132.40.1250.** | 134.40.1250.** | 1210 | 1200 | 50 | 10 | 2X5/M10X1 | 14 | 1512 | 105 | 980 | 71 | 150 | +0.5 | 1200 | ||||||||

| 130.40.1400.** | 131.40.1400.** | 133.40.1400.** | 1595 | 1205 | 220 | 1543 | 1257 | 45 | 26 | 1450 | 1440 | 50 | 10 | 2X5/M10X1 | 12 | 1668 | 136 | 1140 | 96 | 150 | +0.5 | 1300 |

| 132.40.1400.** | 134.40.1400.** | 1360 | 1350 | 50 | 10 | 2X5/M10X1 | 14 | 1666 | 116 | 1134 | 80 | 150 | +0.5 | 1300 | ||||||||

| 130.40.1600.** | 131.40.1600.** | 133.40.1600.** | 1795 | 1405 | 220 | 1743 | 1457 | 48 | 26 | 1650 | 1640 | 50 | 10 | 2X5/M10X1 | 14 | 1876 | 131 | 1330 | 96 | 150 | +0.5 | 1520 |

| 132.40.1600.** | 134.40.1600.** | 1560 | 1550 | 50 | 10 | 2X5/M10X1 | 16 | 1872 | 114 | 1328 | 84 | 150 | +0.5 | 1520 | ||||||||

| 130.40.1800.** | 131.40.1800.** | 133.40.1800.** | 1995 | 1605 | 220 | 1943 | 1657 | 48 | 26 | 1850 | 1840 | 50 | 10 | 2X5/M10X1 | 14 | 2072 | 145 | 1526 | 110 | 150 | +0.5 | 1750 |

| 132.40.1800.** | 134.40.1800.** | 1760 | 1750 | 50 | 10 | 2X5/M10X1 | 16 | 2080 | 127 | 1520 | 96 | 150 | +0.5 | 1750 | ||||||||

| 131.25.2000.03 | 2195 | 1816 | 150 | 2127 | 1885 | 60 | 33 | 2041 | 33 | 13 | 5X3/ZG1/4in | 16 | 2267 | 138 | .. | .. | 105 | 0.9 | 1120 | |||

| 131.45.2000.04 | 2221 | 1779 | 231 | 2155 | 1845 | 60 | 33 | 2059 | 2055 | 54 | 12 | 2X6/M10X1 | 16 | 2304 | 141 | 1696 | 107 | 160 | +0.5 | 2230 | ||

| 130.45.2000.** | 131.45.2000.** | 133.45.2000.** | 2055 | 2033 | 54 | 12 | 2X6/M10X1 | 16 | 2304 | 141 | 1696 | 107 | 160 | +0.5 | 2400 | |||||||

| 132.45.2000.** | 134.45.2000.** | 1967 | 1945 | 54 | 12 | 2X6/M10X1 | 18 | 2304 | 125 | 1692 | 95 | 160 | +0.5 | 2400 | ||||||||

| 130.45.2240.** | 131.45.2240.** | 133.45.2240.** | 2461 | 2019 | 231 | 2395 | 2085 | 60 | 33 | 2295 | 2273 | 54 | 12 | 2X6/M10X1 | 16 | 2560 | 157 | 1920 | 121 | 160 | +0.5 | 2700 |

| 132.45.2240.** | 134.45.2240.** | 2207 | 2185 | 54 | 12 | 2X6/M10X1 | 18 | 2556 | 139 | 1926 | 108 | 160 | +0.5 | 2700 | ||||||||

| 131.45.2500.04 | 2721 | 2279 | 231 | 2655 | 2345 | 72 | 33 | 2555 | 2561 | 54 | 12 | 3X8/M10X1 | 18 | 2826 | 154 | .. | .. | 160 | +0.5 | 2834 | ||

| 130.45.2500.** | 131.45.2500.** | 133.45.2500.** | 2555 | 2533 | 54 | 12 | 2X8/M10X1 | 18 | 2826 | 154 | 2178 | 122 | 160 | +0.5 | 3000 | |||||||

| 132.45.2500.** | 134.45.2500.** | 2467 | 2445 | 54 | 12 | 2X8/M10X1 | 20 | 2820 | 138 | 2180 | 110 | 160 | +0.5 | 3000 | ||||||||

| 130.45.2800.** | 131.45.2800.** | 133.45.2800.** | 3021 | 2579 | 231 | 2955 | 2645 | 72 | 33 | 2855 | 2833 | 54 | 12 | 2X8/M10X1 | 18 | 3114 | 170 | 2484 | 139 | 160 | +0.5 | 3400 |

| 132.45.2800.** | 134.45.2800.** | 2767 | 2745 | 54 | 12 | 2X8/M10X1 | 20 | 3120 | 153 | 2480 | 125 | 160 | +0.5 | 3400 | ||||||||

| 132.45.2800.03 | .. | 2855 | 2833 | 54 | 12 | 3X8/M10X1 | 20 | 3120 | 153 | 160 | +0.5 | 3031 | ||||||||||

| 132.45.2800.12 | .. | 2855 | 2833 | 54 | 12 | 3X8/M10X1 | 18 | 3114 | 170 | .. | ... | 160 | +0.5 | 3010 | ||||||||

| 130.50.3150.** | 131.50.3150.** | 133.50.3150.** | 3432 | 2868 | 270 | 3342 | 2958 | 72 | 45 | 3213 | 3196 | 65 | 12 | 2X8/M10X1 | 20 | 3540 | 174 | 2760 | 139 | 180 | 0.5 | 5000 |

| 132.50.3150.** | 134.50.3150.** | 3104 | 3087 | 65 | 12 | 2X8/M10X1 | 22 | 3542 | 158 | 2750 | 126 | 180 | +0.5 | 5000 | ||||||||

| 130.50.3150.12K | 3103 | 3086 | 50 | 12 | 2X8/M10X1 | 4900 | ||||||||||||||||

| 131.30.3150.12K | 3376 | 2922 | 182 | 3286 | 3014 | 56 | 45 | 3190 | 3180 | 40 | 10 | 3X8/M10X1 | 20 | 3476 | 171 | 120 | +0.5 | 2308 | ||||

| 131.50.3150.12K | 3432 | 2868 | 270 | 3342 | 2958 | 72 | 45 | 3214 | 3197 | 50 | 12 | 2X8/ZG1/4in | 20 | 3540 | 174 | 180 | +0.5 | 5404 | ||||

| 132.50.3150.12K | 3214 | 3197 | 50 | 12 | 2X8/ZG1/4in | 22 | 3542 | 158 | 180 | +0.5 | 5409 | |||||||||||

| 132.50.3150.12K1 | 3214 | 3197 | 50 | 12 | 3X8/M10X1 | 20 | 3536 | 174 | 195 | +0.5 | 5385 | |||||||||||

| 133.50.3150.11K | 3432 | 2868 | 270 | 3342 | 2958 | 60 | 39 | 3103 | 3086 | 50 | 12 | 2X8/M10X1 | 20 | 2760.54 | 139 | 180 | +0.5 | 5174 | ||||

| 133.50.3150.12K | 3103 | 3086 | 50 | 12 | 2X8/M10X1 | 20 | 2760.54 | 139 | 180 | +0.5 | 5174 | |||||||||||

| 133.50.3150.12K1 | 3103 | 3086 | 50 | 12 | 2X8/M10X1 | 18 | 2754.44 | 154 | 180 | +0.5 | 5174 | |||||||||||

| 134.50.3150.11K | 3432 | 2868 | 270 | 3342 | 2958 | 72 | 45 | 3103 | 3086 | 50 | 12 | 2X6/ZG1/4in | 22 | 2758.66 | 126 | 180 | +0.5 | 5104 | ||||

| 130.50.3550.** | 131.50.3550.** | 133.50.3550.** | 3832 | 3268 | 270 | 3742 | 3358 | 72 | 45 | 3613 | 3596 | 65 | 12 | 2X8/M10X1 | 20 | 3940 | 194 | 3160 | 159 | 180 | +0.5 | 5600 |

| 132.50.3550.** | 134.50.3550.** | 3504 | 3487 | 65 | 12 | 2X8/M10X1 | 22 | 3938 | 176 | 3146 | 144 | 180 | +0.5 | 5600 | ||||||||

| 132.50.3550.03K | 3613 | 3596 | 65 | 12 | 3X8/M10X1 | 22 | 3934 | 176 | 180 | +0.5 | 4960 | |||||||||||

| 132.50.3550.12 | 3613 | 3596 | 65 | 12 | 3X8/M10X1 | 22 | 3938 | 176 | 180 | +0.5 | 5318 | |||||||||||

| 130.50.4000.** | 131.50.4000.** | 133.50.4000.** | 4282 | 3718 | 270 | 4192 | 3808 | 80 | 45 | 4063 | 4046 | 65 | 12 | 2X8/M10X1 | 22 | 4400 | 197 | 3608 | 165 | 180 | +0.5 | 6400 |

| 132.50.4000.** | 134.50.4000.** | 3954 | 3937 | 65 | 12 | 2X8/M10X1 | 25 | 4400 | 173 | 3600 | 145 | 180 | +0.5 | 6400 | ||||||||

| 131.50.4000.04K | 4063 | 4046 | 65 | 12 | 2X8/M10X1 | 22 | 4400 | 197 | 180 | +0.5 | 6377 | |||||||||||

| 132.50.4000.12 | 4282 | 3718 | 270 | 4192 | 3908 | 80 | 45 | 4063 | 4046 | 65 | 12 | 3X8/M10X1 | 25 | 4400 | 173 | 180 | +0.5 | 6377 | ||||

| 130.50.4500.40 | 131.50.4500.** | 133.50.4500.** | 4782 | 4218 | 270 | 4692 | 4308 | 80 | 45 | 4563 | 4546 | 65 | 12 | 2X8/M10X1 | 22 | 4906 | 220 | 4114 | 188 | 185 | +0.5 | 6942 |

| 132.50.4500.** | 134.50.4500.** | 4454 | 4437 | 65 | 12 | 2X8/M10X1 | 25 | 4900 | 193 | 4100 | 165 | 185 | +0.5 | |||||||||

| 131.50.4500.04 | 4565 | 4546 | 60 | 12 | 3X8/M10X1 | 20 | 4880 | 242 | 185 | +0.5 | 7250 | |||||||||||

| 132.50.4500.04 | 4565 | 4546 | 60 | 12 | 2X10/M14X1.5 | 25 | 4895 | 193 | 185 | +0.5 | 7333 | |||||||||||

| 131.60.5000.04 | 5320 | 4670 | 320 | 5220 | 4766 | 45 | 5082 | 5062 | 65 | 18 | 3X8/M10X1 | 20 | 5440 | 270 | 220 | +0.5 | 11752 | |||||