girth gear

-

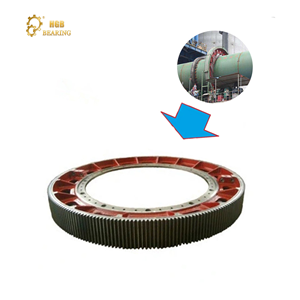

Segmented large gear rings

Segmented large gear rings are important components in industrial reducers, mainly used to drive large rotating systems such as dryers, rotary kilns, horizontal mills, etc.

Email Details -

Drying machine large gear ring

In dryers and dryers, the role of the large gear ring is crucial, usually used to transmit power and support rotating components. Through reasonable material selection, design, and maintenance, the stable and reliable performance of the large gear ring can be ensured, providing strong support for the long-term operation of the equipment. The large gear ring transmits the power of the motor to the rotating parts of the equipment through meshing with the small gear, thereby driving the operation of the equipment. The large gear ring is generally made of high-strength materials, such as cast steel or alloy steel, to ensure that it can withstand the strong forces and high temperatures generated during equipment operation. The accuracy and wear resistance of the large gear ring directly affect the service life and efficiency of the equipment.

large gear ring customized large gear ring Non standard customized product solution provider high quality gear ringEmail Details -

Factory direct sales prices can be customized for herringbone helical gear large gear rings

1.Herringbone gears combine the advantages of helical gears (high load capacity) and spur gears (no axial force). 2.Herringbone gears can transmit high torque due to their relatively long tooth length (due to the inclination). However, the complex and therefore expensive production of this gear type is limited to special applications. (e.g. for large transfers)

Email Details -

Excellent team factory with high quality rotary kiln large girth gear ring

Large ring gear is fully tempered and quenched , so that it has good comprehensive mechanical properties, and has good plasticity and toughness while ensuring high strength. To provide customers with ring gear castings with high service life and high operating rate.

Email Details -

Customizable factory production and sales of ball mill large gear rings

1.The large ring gear is one of the important components of rotary kiln, ball mill, dryer and other machinery, so the quality of the ring gear is related to the stability and service life of the ball mill and rotary kiln. 2.The large ring gear is a very critical component in the transmission device of ball mills and rotary kilns. It drives the entire cylinder to rotate at low speed for a long time. Its quality directly affects the smoothness of the transmission system of ball mills and rotary kilns, the stability of operation, and the quality of the lining. The service life and the operation rate of the kiln and the grinding mill, so the quality requirements of the large ring gear in actual production are very high.

Email Details -

Custom Cast Steel 45 Ball Mill Rotary Kiln Dryer Girth Gear Wheel Large Diameter Ring Gear

1)Selecting high-quality raw materials and strictly controlling the production process; 2) Using LF refining furnace and VD vacuum degassing furnace to ensure the internal quality of ring gear castings; 3) During the casting process, CAE simulation pouring software is used to assist the design process, so as to modify the pouring model in time , so as to better control the quality of the ring gear blank; 4) Large ring gear is fully tempered and quenched , so that it has good comprehensive mechanical properties, and has good plasticity and toughness while ensuring high strength. To provide customers with ring gear castings with high service life and high operating rate.

Email Details -

Hot

Customized Large Ring Gear Spur Gear Girth gear

Ring gear, Gear wheel or Girth gear is a part used in mechanical transmission. Material is usually forged or casting alloy steel with surface carburizing or hardening treatment. The gear has the high bearing capacity and durability in practical application, which is widely used in high speed and heavy load machinery because of its stable transmission, low impact, vibration and noise. The ring gear from our company is precisely designed using high quality raw material, and finish of the gear is with high precision too.Our quality experts check the product at each and every stage of manufacturing process according to the international industrial standards. Our company can produce different type gear ring and wheel such as spur gear, helical gear, worm gear, large ring gear according to the customer's drawing and requirements. Our product is highly appreciated amongst customers for its dimensional accuracy, excellent strength and high performance. Teeth quenching, teeth grinding and surface treatment like oxide, nitriding, sandblasting are also available.

Email Details -

High Precision Large Internal Ring Gear Girth gear Metal Spur Gear With Nitriding Treatment

Ring gear is made of 42CrMo quenched and tempered material. Module is 4.5 and teeth No. is 69. To improve the hardness of the gear, we make nitriding treatment for it. The holding temperature of the nitriding process is generally 460-600 ℃, which is a chemical heat treatment process in which active nitrogen atoms are infiltrated into the surface of the gear. After nitriding, the distortion of the gear is small, and it has higher hardness than carburizing, which can increase wear resistance, fatigue strength, anti-seizure performance, corrosion resistance and high temperature softening resistance, etc. It is widely used in automobiles and machine tools for higher requirements of wear resistance capacity.

Email Details