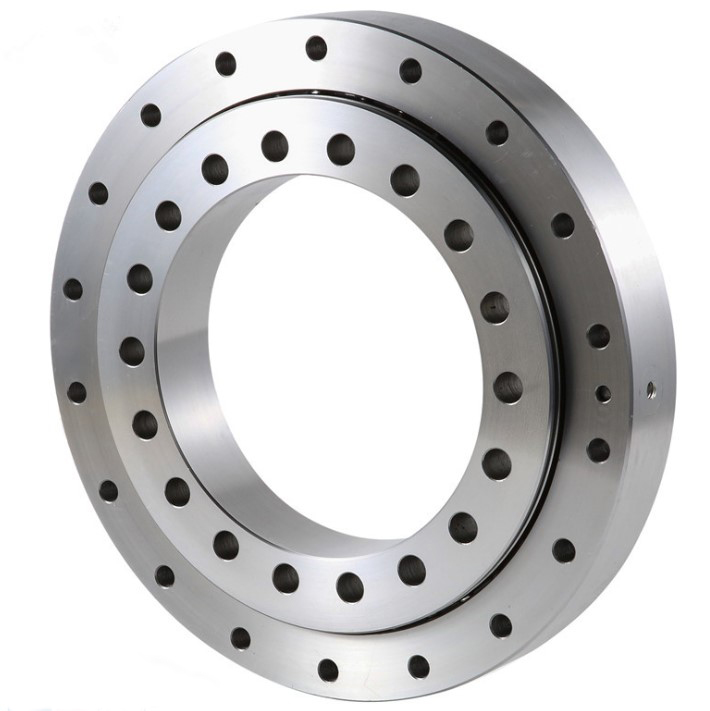

Cross Roller Slewing Bearing

-

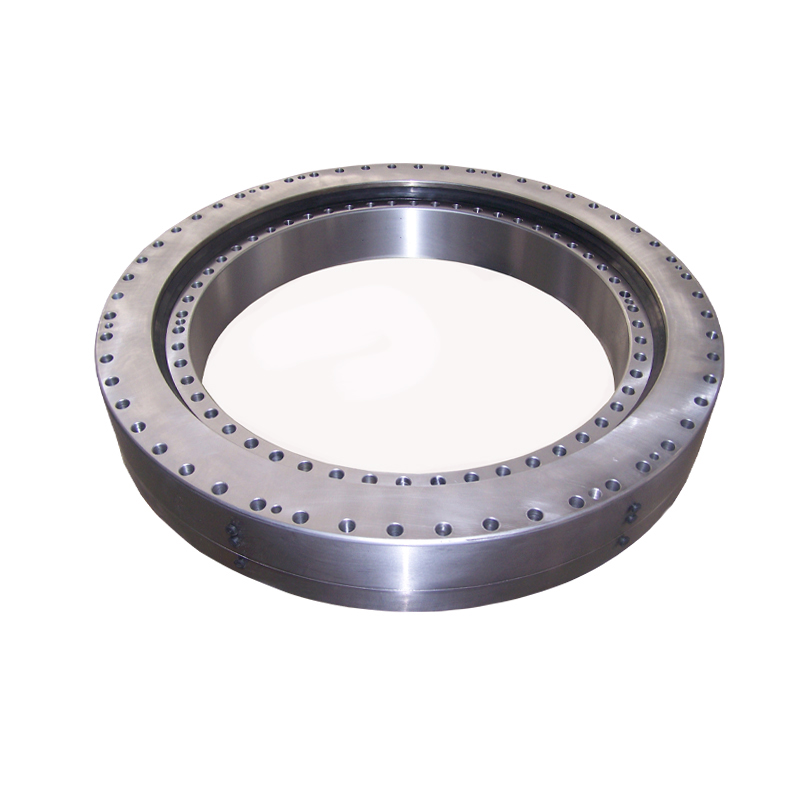

Large toothless slewing bearing

Large toothless slewing bearing is a large bearing that can withstand comprehensive loads. It has the characteristics of simple structure, strong load-bearing capacity, and smooth operation. We have a professional technical sales team to guarantee both quality and service. We can design and produce according to customer requirements. , repair, replacement and other services.

Email Details -

High technology and high precision rotary bearings Experienced manufacturer

Crossed roller slewing bearing products have remarkable features.

Email Details

1. It shows high bearing capacity and can withstand large loads.

2. The product has high rotation accuracy to ensure smooth and error-free operation. Its structure is compact and reliable, which improves its service life.

3. This product has small friction loss, can reduce energy consumption and improve economic benefits.

4. It saves installation space, has strong adaptability and is easy to deploy. The high rotation speed capability can meet the efficient operation needs of various types of equipment. It has strong impact resistance and can operate stably even in harsh working environments.

5. Adequate lubrication, effectively reducing wear and extending service life -

Customizable special-shaped slewing bearing

We provide customizable special-shaped slewing bearings, which are tailored to meet the specific needs of different mechanical equipment. Our special-shaped slewing bearings have the characteristics of high precision, high load capacity and low friction coefficient, ensuring the stable operation of the equipment in complex environments.

Email Details -

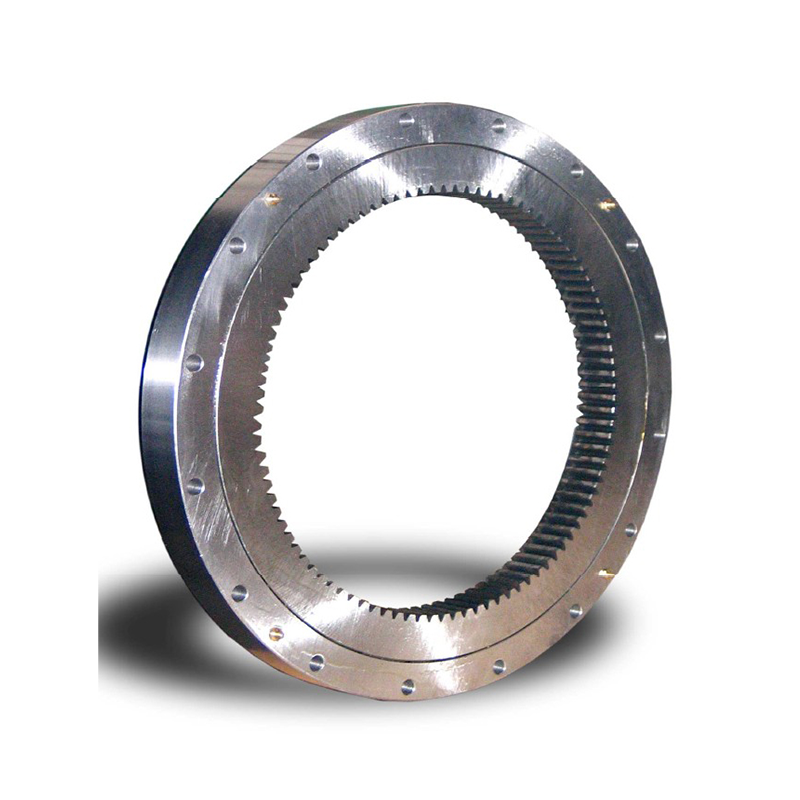

slewing bearing of mining machinery

Mining machinery slewing bearings are key components in mining machinery and equipment and are widely used in various mining and processing equipment. This slewing bearing enjoys a wide reputation in the field of mining machinery for its excellent performance, stable quality and long service life. Our company can design, customize, replace, etc. according to customer requirements

Email Details -

Carrying large customizable heavy duty machinery slewing bearings

The single-row crossed roller slewing bearing is composed of two seat rings. It has a compact structure, light weight, high manufacturing precision, small assembly clearance, and high requirements for installation accuracy. The rollers are arranged in a 1:1 cross and can bear the bearings at the same time. It has axial force, overturning moment and large radial force, and is widely used in lifting, transportation and engineering machinery products.

Email Details -

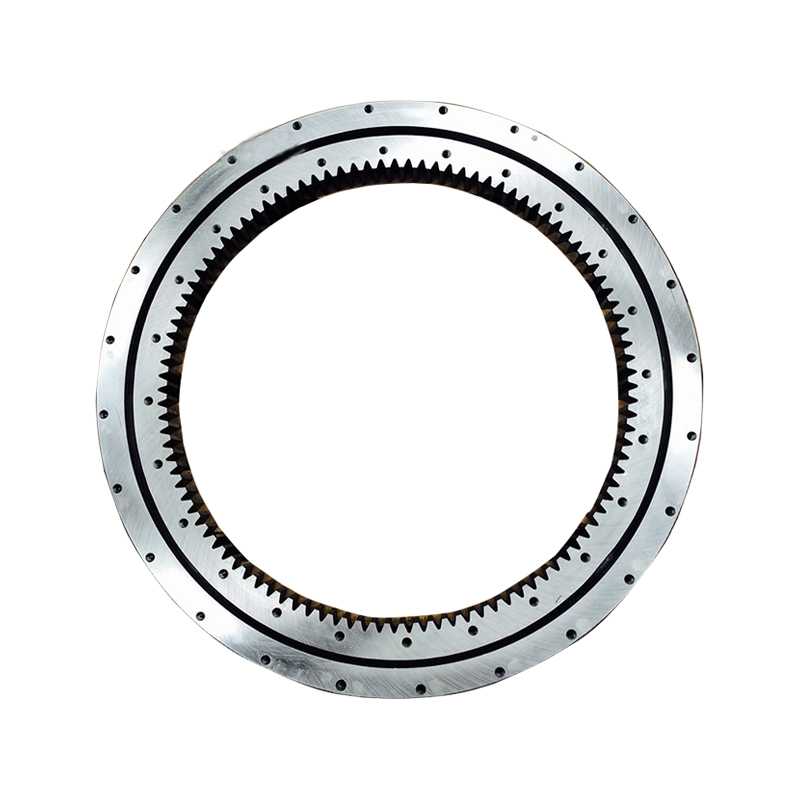

High quality factory direct sales custom slewing bearing

Crossed roller slewing bearing is a key component commonly used in construction machinery and lifting equipment.

Email Details

It has the advantages of strong load-bearing capacity, flexible rotation and long service life.

Crossed roller slewing bearing, referred to as slewing bearing, is a slewing bearing with rolling elements.

Bearing, commonly used in construction machinery and lifting equipment. It realizes return through the rolling of rolling elements

Rotating motion, bearing and transmitting loads, while having high stiffness and load-bearing capacity. -

Single Row Cross Roller Slewing Ring Turntable Bearing (HJ Series)

The single-row cross-roller slewing bearing consists of two rings, with compact structure, high manufacturing accuracy, small assembly clearance, and high requirements for installation accuracy. It can bear overturning moment and large radial force and it is widely used in transportation, construction machinery and military products.

Email Details

There are two basic working modes: 1. The inner ring fixes , and the outer ring rotates; 2. The outer ring fixes and the inner ring rotates. The raceways of the slewing bearing are all treated by surface induction hardening, and the quenching hardness is guaranteed to be HRC55~62, which can achieve sufficient hardened layer depth.

Slewing bearing is usually made with internal teeth, external teeth or no teeth. The heat treatment of gears is generally normalized or quenched and tempered. The tooth surface can also be quenched according to the user's requirements, the quenching hardness is HRC50-60, and sufficient depth can be guaranteed. Teeth grinding is also supported. -

Single Row Cross Roller Slewing Bearing (11 Series)

The single row cross roller slewing bearing is made of two seat rings. It is featured with compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross- arranged through spacers. It can bear axial force, overturning moment and large radial force at the same time. Compared with ball slewing ring, the axial and radial clearance of the cross roller slewing ring is smaller than single row ball slewing bearing. While the rotating is not so flexible as the single row ball slewing bearings, usually it is used for some higher precision applications. It is widely used in lifting transportation, construction machinery, military product, robots, medical equipment, grinding and drilling machine etc.

Email Details

Standard material we adopt is 50Mn and 42CrMo. Other customized material is also acceptable. We support models selection based on your application; teeth quenching and grinding; customized surface treatment like Blackening, phosphating, galvanizing, sandblasting and etc. -

High Precision Slewing Bearing For Filling Machine

Light series slewing bearings are usually used on filling machine, which has the same structure as ordinary slewing bearing, but it has the characteristics of lightweight, flexible rotation, compact structure and low friction. This kind of slewing ring bearing is widely used in food machinery, filling machinery, beverage machinery, blow molding machine, packaging machinery, injection molding machine, environmental protection machinery, and other fields. It is with features of low noise, high precision and high performance.

Email Details

Adhering to the international advanced management concept, we are committed to providing a complete set of bearing solutions, from raw material control, rolling element, cage and anti-rust oil, grease, bearing lathe processing, heat treatment to rough grinding and fine grinding, bearing packaging and delivery, after-sales service , installation guidance, all-round service in accordance with international standards