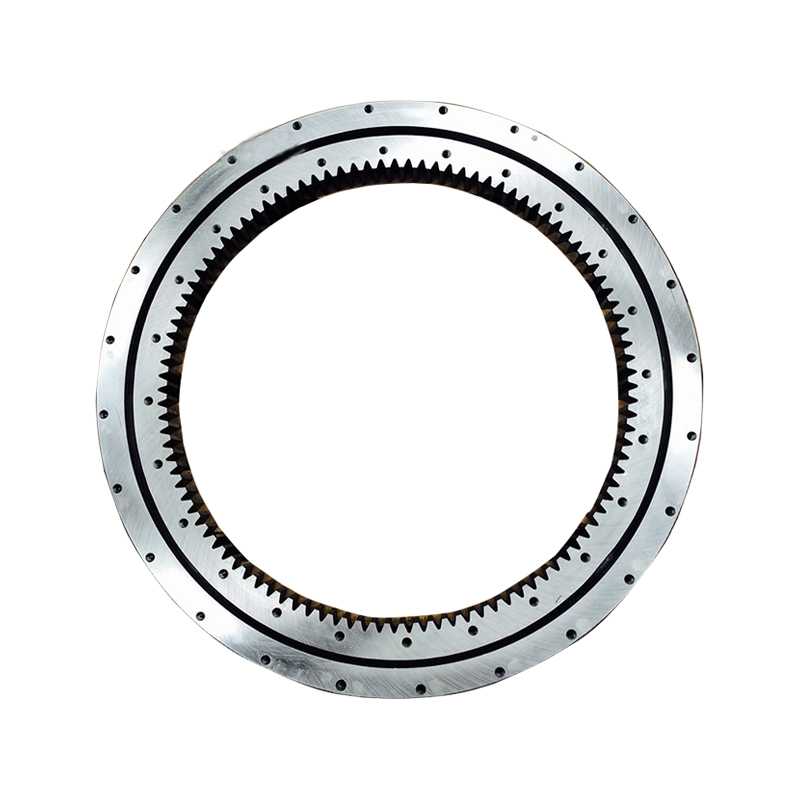

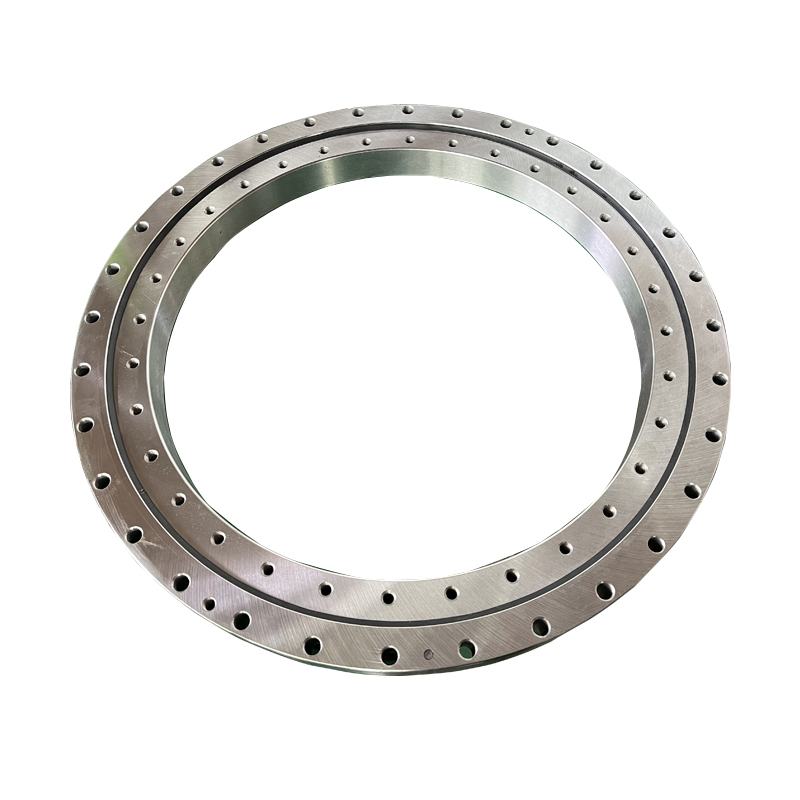

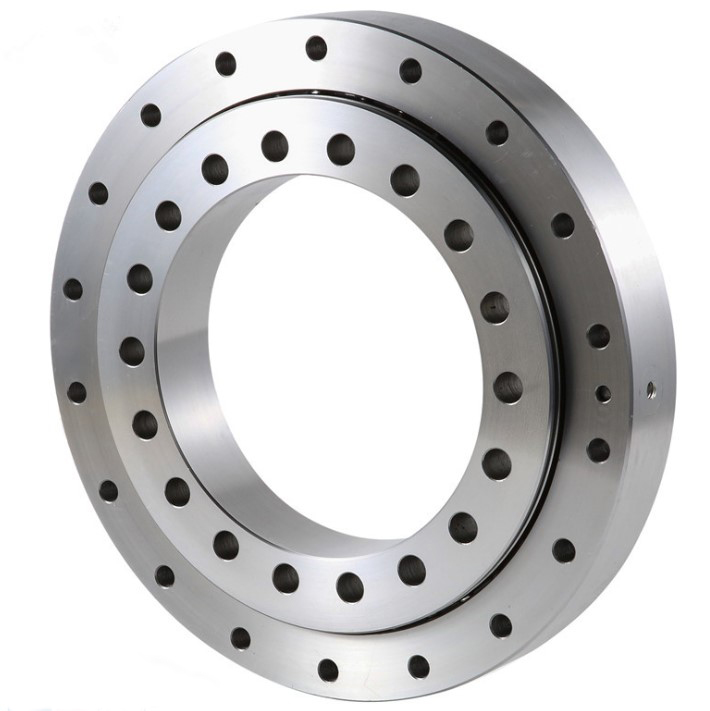

Single Row Cross Roller Slewing Bearing (11 Series)

- LYHGB

- LUOYANG

- 45 DAYS

- 4000 SETS/MONTH

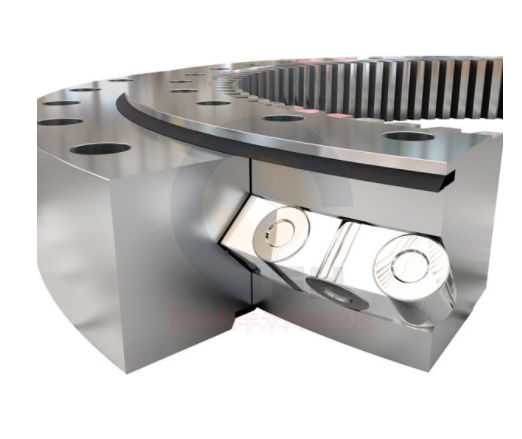

The single row cross roller slewing bearing is made of two seat rings. It is featured with compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross- arranged through spacers. It can bear axial force, overturning moment and large radial force at the same time. Compared with ball slewing ring, the axial and radial clearance of the cross roller slewing ring is smaller than single row ball slewing bearing. While the rotating is not so flexible as the single row ball slewing bearings, usually it is used for some higher precision applications. It is widely used in lifting transportation, construction machinery, military product, robots, medical equipment, grinding and drilling machine etc.

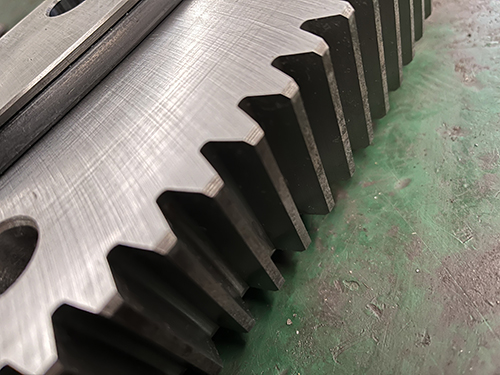

Standard material we adopt is 50Mn and 42CrMo. Other customized material is also acceptable. We support models selection based on your application; teeth quenching and grinding; customized surface treatment like Blackening, phosphating, galvanizing, sandblasting and etc.

High precision single row cross roller slewing bearing (11 Series)

Structural characteristics

The single row cross roller slewing bearing is made of two seat rings. It is featured with compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross- arranged through spacers. It can bear axial force, overturning moment and large radial force at the same time. In addition, the crossed roller slewing bearing does not cause one-sided contact or locking of the rollers. At the same time, because the inner and outer rings of the standard crossed roller slewing bearing are divided structures, the clearance can be adjusted even if a preload is applied.

Features

The advantages of crossed roller slewing bearing over ordinary slewing bearing:

1. The accuracy level that the cross-roller slewing bearing can achieve is much higher as well as the radial runout and axial runout compared with ordinary slewing bearing.

2. Cross roller slewing bearing is with high stiffness and rigidity and also suitable for low-noise working environment.

3. The structure of crossed roller slewing bearings is relatively simple. By means of a row of cylindrical rolling elements arranged in a row on a single raceway, a fairly large bearing can be obtained. In order to achieve the same effect, ordinary slewing bearings must be sequentially arranged on three rows of raceways through three rows of cylindrical rolling elements. In this way, the crossed roller slewing bearing takes up much less space and is lighter in weight than the ordinary three-row roller slewing bearing, which brings great convenience in design and assembly.

Technical Parameters

| Bearing type | Boundary dimensions | Mounting hole diameter | Structure dimensions | Gear parameters | Mass KG | |||||||||||||||||

| Non-gear type | External gear type | Internal gear type | D | d | H | D1 | D2 | n | φ | D3 | d1 | H1 | h | n3 | m | Ext gear | Int gear | b | x | |||

| mm | mm | mm | mm | Da | Z | da | Z | mm | ||||||||||||||

| 110.25.500** | 111.25.500.** | 113.25.500.** | 602 | 398 | 75 | 566 | 434 | 20 | 18 | 499 | 501 | 65 | 10 | 4/M10X1 | 5 | 630 | 123 | 365 | 74 | 60 | +0.5 | 80 |

| 112.25.500.** | 114.25.500.** | 6 | 630 | 120 | 360 | 62 | 60 | +0.5 | 80 | |||||||||||||

| 110.25.560** | 111.25.560.** | 113.25.560.** | 662 | 458 | 75 | 626 | 494 | 20 | 18 | 558.5 | 561.5 | 65 | 10 | 4/M10X1 | 5 | 690 | 135 | 425 | 86 | 60 | +0.5 | 90 |

| 112.25.560.** | 114.25.560.** | 6 | 690 | 112 | 426 | 72 | 60 | +0.5 | 90 | |||||||||||||

| 110.25.630** | 111.25.630.** | 113.25.630.** | 732 | 528 | 75 | 696 | 564 | 24 | 18 | 628.5 | 631.5 | 65 | 10 | 4/M10X1 | 6 | 774 | 126 | 492 | 83 | 60 | +0.5 | 100 |

| 112.25.630.** | 114.25.630.** | 8 | 776 | 94 | 448 | 62 | 60 | +0.5 | 100 | |||||||||||||

| 110.25.710** | 111.25.710.** | 113.25.710.** | 812 | 608 | 75 | 776 | 644 | 24 | 18 | 708.5 | 711.5 | 65 | 10 | 4/M10X1 | 6 | 852 | 139 | 568 | 80 | 65 | +0.5 | 170 |

| 112.25.710.** | 114.25.710.** | 8 | 856 | 104 | 632 | 64 | 65 | +0.5 | 170 | |||||||||||||

| 110.28.800** | 111.28.800.** | 113.28.800.** | 922 | 678 | 82 | 878 | 722 | 30 | 22 | 798.5 | 801.5 | 72 | 10 | 6/M10X1 | 6 | 852 | 139 | 568 | 80 | 65 | +0.5 | 170 |

| 112.28.800.** | 114.28.800.** | 8 | 856 | 104 | 632 | 64 | 65 | +0.5 | 170 | |||||||||||||

| 110.28.900** | 111.28.900.** | 113.28.900.** | 1022 | 778 | 82 | 978 | 822 | 30 | 22 | 898.5 | 901.5 | 72 | 10 | 6/M10X1 | 8 | 1064 | 130 | 736 | 93 | 65 | +0.5 | 190 |

| 112.28.900.** | 114.28.900.** | 10 | 1070 | 104 | 730 | 74 | 65 | +0.5 | 190 | |||||||||||||

| 110.28.1000** | 111.28.1000.** | 113.28.1000.** | 1122 | 878 | 82 | 1078 | 922 | 36 | 22 | 998.5 | 1001.5 | 72 | 10 | 6/M10X1 | 10 | 1190 | 116 | 820 | 83 | 65 | +0.5 | 210 |

| 112.28.1000.** | 114.28.1000.** | 12 | 1188 | 96 | 816 | 69 | 65 | +0.5 | 210 | |||||||||||||

| 110.28.1120** | 111.28.1120.** | 113.28.1120.** | 1242 | 998 | 82 | 1198 | 1042 | 36 | 22 | 1118 | 1122 | 72 | 10 | 6/M10X1 | 10 | 1300 | 127 | 940 | 95 | 65 | +0.5 | 230 |

| 112.28.1120.** | 114.28.1120.** | 12 | 1308 | 106 | 936 | 79 | 65 | +0.5 | 230 | |||||||||||||

| 110.32.1250** | 111.32.1250.** | 113.32.1250.** | 1540 | 1110 | 91 | 1337 | 1163 | 40 | 26 | 1248 | 1252 | 81 | 10 | 6/M10X1 | 12 | 1452 | 118 | 1044 | 88 | 75 | +0.5 | 350 |

| 112.32.1250.** | 114.32.1250.** | 14 | 1456 | 101 | 1036 | 75 | 75 | +0.5 | 350 | |||||||||||||

| 110.32.1400** | 111.32.1400.** | 113.32.1400.** | 1540 | 1260 | 91 | 1478 | 1313 | 40 | 26 | 1398 | 1402 | 81 | 10 | 6/M10X1 | 12 | 1608 | 131 | 1188 | 100 | 75 | +0.5 | 400 |

| 112.32.1400.** | 114.32.1400.** | 14 | 1610 | 112 | 1190 | 86 | 75 | +0.5 | 400 | |||||||||||||

| 110.32.1600** | 111.32.1600.** | 113.32.1600.** | 1740 | 1460 | 91 | 1687 | 1513 | 45 | 26 | 1598 | 1602 | 81 | 10 | 8/M10X1 | 14 | 1820 | 127 | 1386 | 100 | 75 | +0.5 | 440 |

| 112.32.1600.** | 114.32.1600.** | 16 | 1824 | 111 | 1376 | 87 | 75 | +0.5 | 440 | |||||||||||||

| 110.32.1800** | 111.32.1800.** | 113.32.1800.** | 1940 | 1660 | 91 | 1887 | 1713 | 45 | 33 | 1798 | 1802 | 81 | 10 | 8/M10X1 | 14 | 2016 | 141 | 1568 | 113 | 75 | +0.5 | 500 |

| 112.32.1800.** | 114.32.1800.** | 16 | 2016 | 123 | 1568 | 99 | 75 | +0.5 | 500 | |||||||||||||

| 113.45.1830.11 | 2002 | 1665 | 156 | 1940 | 1720 | 54 | 30 | 1827 | 1833 | 128 | 28 | 6/M10X1 | 12 | 1610 | 135 | 100 | +0.5 | 912 | ||||

| 110.40.2000** | 111.40.2000.** | 113.40.2000.** | 2178 | 1825 | 112 | 2110 | 1891 | 48 | 33 | 1998 | 2002 | 100 | 12 | 8/M10X1 | 16 | 2272 | 139 | 1728 | 109 | 90 | +0.5 | 900 |

| 112.40.2000.** | 114.40.2000.** | 18 | 2268 | 123 | 1728 | 97 | 90 | +0.5 | 900 | |||||||||||||

| 110.40.2000.12 | 2178 | 1825 | 112 | 2110 | 1891 | 48 | 33 | 1991 | 1995 | 100 | 12 | 8/M10X1 | ... | .... | ... | ... | ... | ... | ... | 767 | ||

| 110.40.2240** | 111.40.2240.** | 113.40.2240.** | 2418 | 2065 | 112 | 2350 | 2131 | 48 | 33 | 2237.5 | 2242.5 | 100 | 12 | 8/M10X1 | 16 | 2496 | 153 | 1984 | 125 | 90 | +0.5 | 1000 |

| 112.40.2240.** | 114.40.2240.** | 18 | 2502 | 136 | 1980 | 111 | 90 | +0.5 | 1000 | |||||||||||||

| 110.40.2500** | 111.40.2500.** | 113.40.2500.** | 2678 | 2325 | 112 | 2610 | 2391 | 56 | 33 | 2497.5 | 2502.5 | 100 | 12 | 8/M10X1 | 18 | 2772 | 151 | 2232 | 125 | 90 | +0.5 | 876 |

| 112.40.2500.** | 114.40.2500.** | 20 | 2780 | 136 | 2220 | 112 | 90 | +0.5 | 876 | |||||||||||||

| 110.40.2800** | 111.40.2800.** | 113.40.2800.** | 2978 | 2625 | 112 | 2910 | 2691 | 56 | 33 | 2797.5 | 2802.5 | 100 | 12 | 8/M10X1 | 18 | 3078 | 168 | 2520 | 141 | 90 | +0.5 | 1250 |

| 112.40.2800.** | 114.40.2800.** | 20 | 3080 | 151 | 2520 | 127 | 90 | +0.5 | 1250 | |||||||||||||

| 110.50.3150** | 111.50.3150.** | 113.50.3150.** | 3376 | 2922 | 134 | 3286 | 3014 | 56 | 45 | 3147.5 | 3152.5 | 122 | 12 | 8/M10X1 | 20 | 3480 | 168 | 2520 | 141 | 110 | +0.5 | 2150 |

| 112.50.3150.** | 114.50.3150.** | 22 | 3476 | 151 | 2520 | 127 | 110 | +0.5 | 2150 | |||||||||||||

| 110.50.3550** | 111.50.3150.** | 113.50.3150.** | 3776 | 3322 | 134 | 3686 | 3414 | 56 | 45 | 3547.5 | 3552.5 | 122 | 12 | 8/M10X1 | 20 | 3880 | 191 | 3220 | 162 | 110 | +0.5 | 2470 |

| 112.50.3150.** | 114.50.3150.** | 22 | 3894 | 174 | 3212 | 147 | 110 | +0.5 | 2470 | |||||||||||||

| 110.50.4000** | 111.50.4000.** | 113.50.4000.** | 4226 | 3772 | 134 | 4136 | 3864 | 60 | 45 | 3997.5 | 4002.5 | 122 | 12 | 10/M10X1 | 22 | 4334 | 194 | 3652 | 167 | 110 | +0.5 | 2800 |

| 112.50.4000.** | 114.50.4000.** | 25 | 4350 | 171 | 3650 | 147 | 110 | +0.5 | 2800 | |||||||||||||

| 110.50.4500** | 111.50.4500.** | 113.50.4500.** | 4726 | 4272 | 134 | 4636 | 4364 | 60 | 45 | 4497.5 | 4502.5 | 122 | 12 | 10/M10X1 | 22 | 4940 | 217 | 4158 | 190 | 110 | +0.5 | 3100 |

| 112.50.4500.** | 114.50.4500.** | 25 | 4850 | 191 | 4150 | 167 | 110 | +0.5 | 3100 | |||||||||||||

Product Service

According to the requirements of ISO 9001-2008, HGB has established a set of standard quality control system, from raw material procurement to product information feedback. We have detailed documentation and reports. All testing tools of the product are rechecked twice a year.

Material quality control: The materials are made of steel ingots from well-known steel factories, purchased from large forging factories. All forgings have regular quality certificates of ingots and forging qualification certificates.

HGB inspector and purchasing department are responsible for the production process report of all forged parts.

The material will be re-inspected before entering the HCB factory, HGB inspector will inspect every forging to confirm the quality of forgings.

All our products can provide CCS, ABS, DNV, GL certificates and provide third-party inspection.

Pre-sale service

Bearing technology, installation and consulting services.

Fully communicate with customers, understand customer needs in detail.

Sales of services

Implement the relevant provisions of ISO 9001:2008 quality management system.

Arrange a business person for each customer and provide 24-hour service.

Provide customers with real, complete and effective contract documents.

When the customer requests, it can be sent to the customer’s installation site for customer inspection.

With the consent of customers, all kinds of factory inspection are carried out before leaving the factory to ensure the correct and clear marking, packaging and specifications, safe and fast transportation and timely delivery.

After-sale service

To fulfill the contract, We will send the customer a feedback form after using the product. So that we can improve our work in the future and to better service our customers.

Application of three guarantees to our products, for quality problems of user feedback, telephone reply within 4 hours and on-site treatment within 24 hours.

After the product is sold, free technical consultation service will be provided for life! A cooperation, lifelong friend!