Ball Slewing Bearing

-

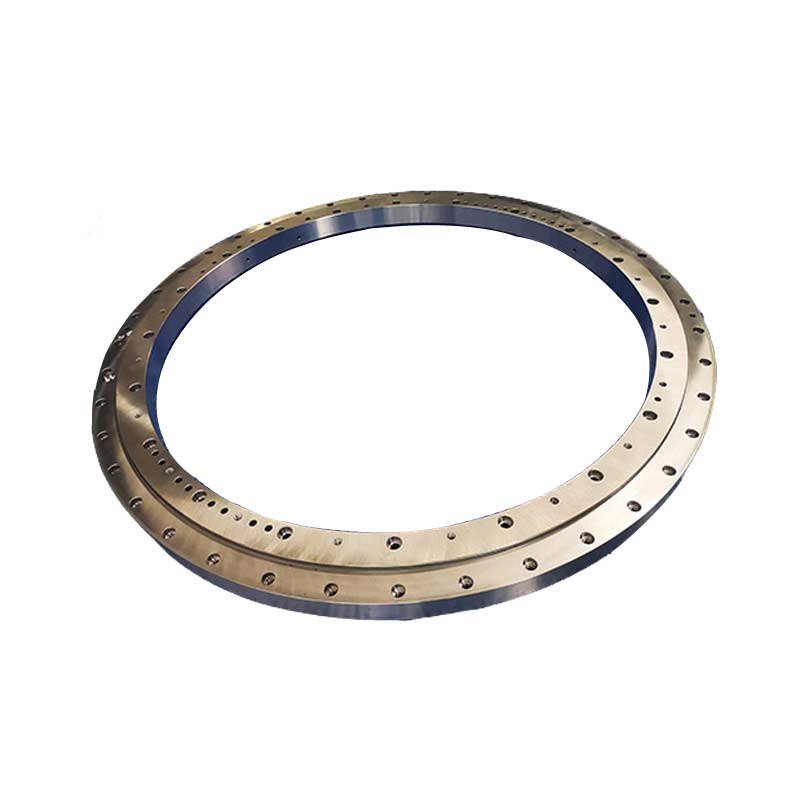

Single Row Four Point Contact Ball Slewing Ring( Q Series)

Single row four point contact ball slewing ring Q series is a standard model series in China. Q means single row ball type. QW is external gear type, QN is internal gear type, QU is non gear type. It is made of two seat rings. The balls and the raceway are with four points contact, via which the axial force, radial force and resultant moment is born simultaneously. Outer Diameter is from 360 mm to 4700mm.

Email Details

Standard material we adopt is 50Mn and 42CrMo. Other customized material is also acceptable. We support models selection based on your application; teeth quenching and grinding; customized surface treatment like Blackening, phosphating, galvanizing, sandblasting and etc.

In the production process of slewing ring bearing, whole process inspection is implemented strictly to ensure that each set of products are qualified. For high-precision products, precise grinding is used to effectively control the parameters of ring ellipse, wall thickness and flatness, so as to ensure that the precision of finished products meets the requirements of standards or customer drawings.

This series models are with advantage of compact design, flexible rotating and light weight. It is widely used on rotary conveyor, welding arm and positioner, light/medium duty cranes, excavators and other engineering machines. Please feel free to tell us the application you use and we can help you choose the proper model and offer you a professional solution as soon as possible. -

High Precision Low Noise Slew Bearing For CT Scanner Machine

Slew Bearing For CT Scanner Machine is featured with high precision, high speed and low noise.

Email Details

Firstly, the 42CrMo quenched and tempered material is used to make the material performance better and more stable, which guarantees the product quality from the source;

Secondly, the product raceway and appearance are comprehensively polished to ensure high product precision;

Thirdly, for the product's silent requirements, a special segmented nylon cage device is used to lock the ball in the cage pocket while ensuring that the steel ball can rotate freely, thereby reducing the noise impact caused by the free movement of the cage in the raceway. Reduce rotating noise. Through the above efforts, we ensure that the finished products of the slewing ring meet various technical requirements. -

Yaw Bearing For Wind Turbine Generator

The wind turbine yaw bearing is installed at the connection between the tower and the cockpit, and the pitch bearing is installed at the connection between the root of each blade and the hub. Each wind turbine uses one set of yaw bearing and three sets of pitch bearing. The material of the yaw and pitch bearing rings is 42CrMo, the heat treatment adopts the overall quenching and tempering treatment, and the surface of the raceway is quenched. The force of yaw and pitch bearings is complex, and the impact and vibration are relatively large. Therefore, the bearing is required to withstand both impact and large load. The life of the wind turbine main engine requires 20 years, and the cost of bearing installation is relatively large, so the life of the yaw and pitch bearings is required to reach 20 years. The hardness of the bearing ring base is 240-280HB, which can withstand impact without plastic deformation. At the same time, the surface quenching hardness of the raceway reaches 55-62HRC, which can increase the contact fatigue life and ensure the service life of the bearing.

Email Details