What are the steps for making a slewing bearing?

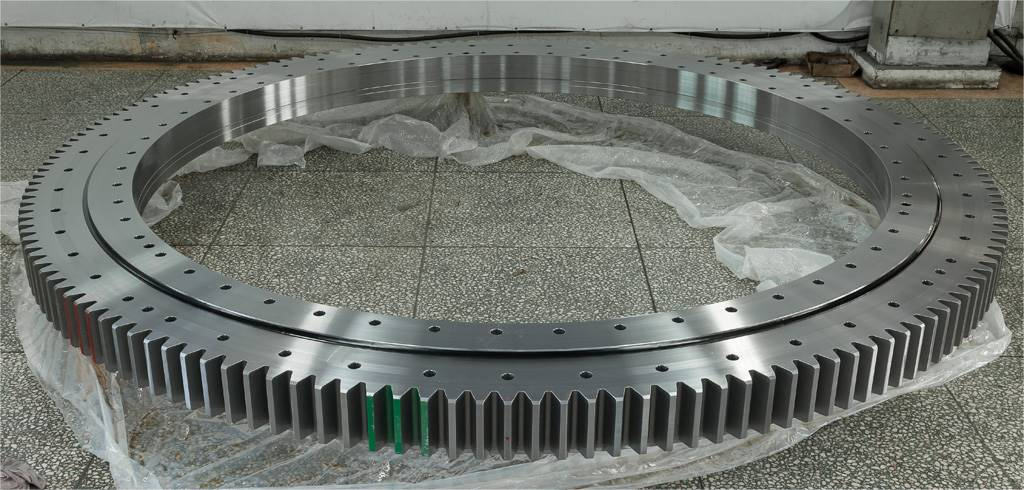

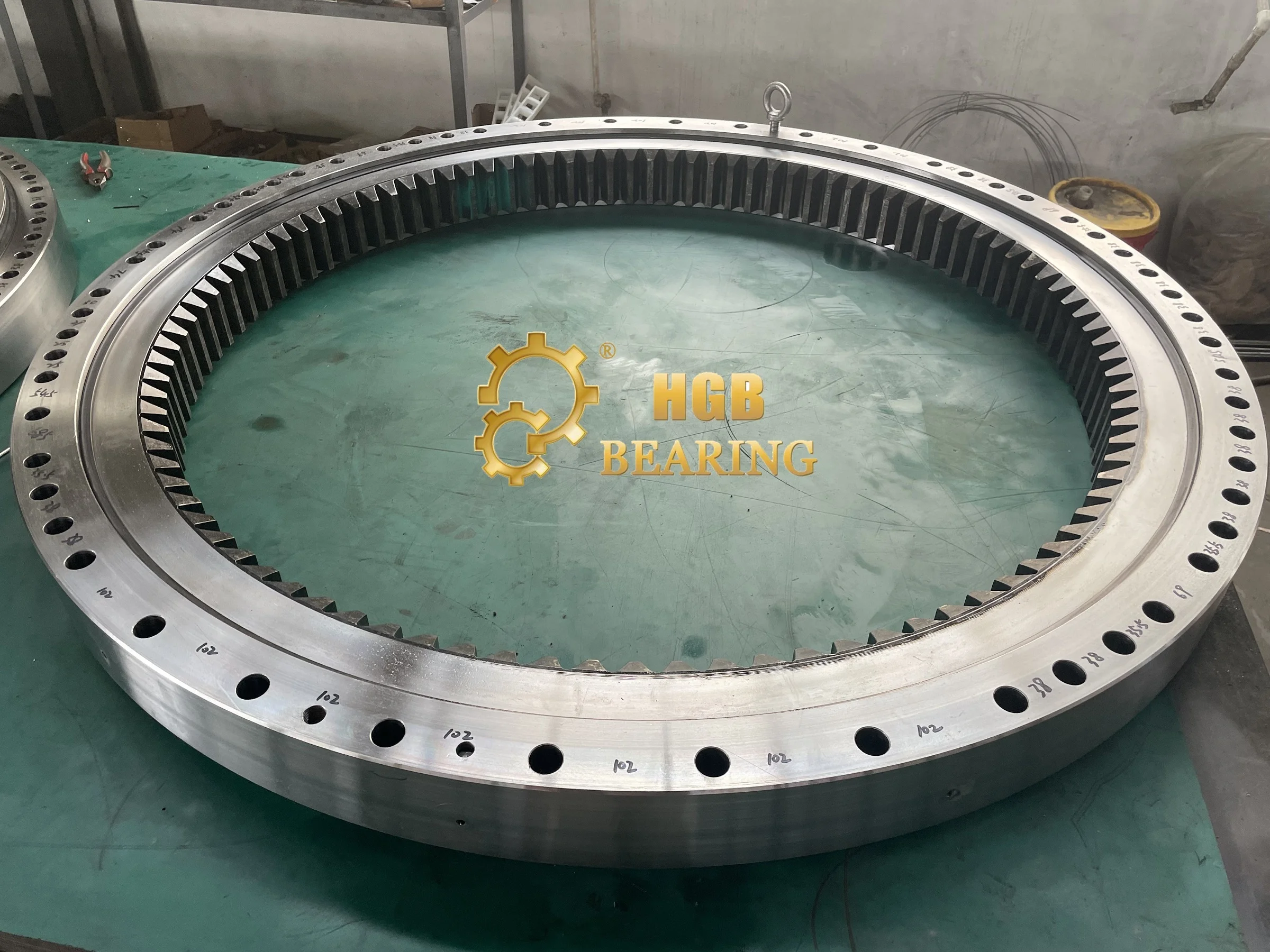

The slewing bearing is changed from the original four-point contact ball slewing bearing with external teeth to a three-row roller slewing bearing with external teeth. While the standard parameters of the equipment remain unchanged (to ensure that it can be installed), the structure of the bearing is changed. In order to increase the load-bearing capacity of the slewing bearing, sometimes other types of surface-hardened steel are used to meet the needs of the host in special applications.

Such as 42CrMo, 5CrMnMo, etc. The codes for the ferrule material and blank supply status are according to the rules in the table. "T" in the table indicates that the ferrule blank is supplied in a quenched and tempered state. The rotating support rolling bodies are generally separated by individual nylon isolation blocks. Separated, this structure can maintain the stability of movement, and the service life of the slewing bearing can be completely extended.

Regarding the delamination of the raceway, we must first make a correct judgment. When delamination occurs, it is generally not easy to see outside. According to our experience, when the following conditions occur, it means that the raceway has delamination: When the host rotates with load, the raceway There is a "cluck-cluck" abnormal sound everywhere, the reversal speed is uneven or the speed in a certain direction is significantly slowed down with slight vibration; the temperature rise of the reversing motor is too high or the current is too large.