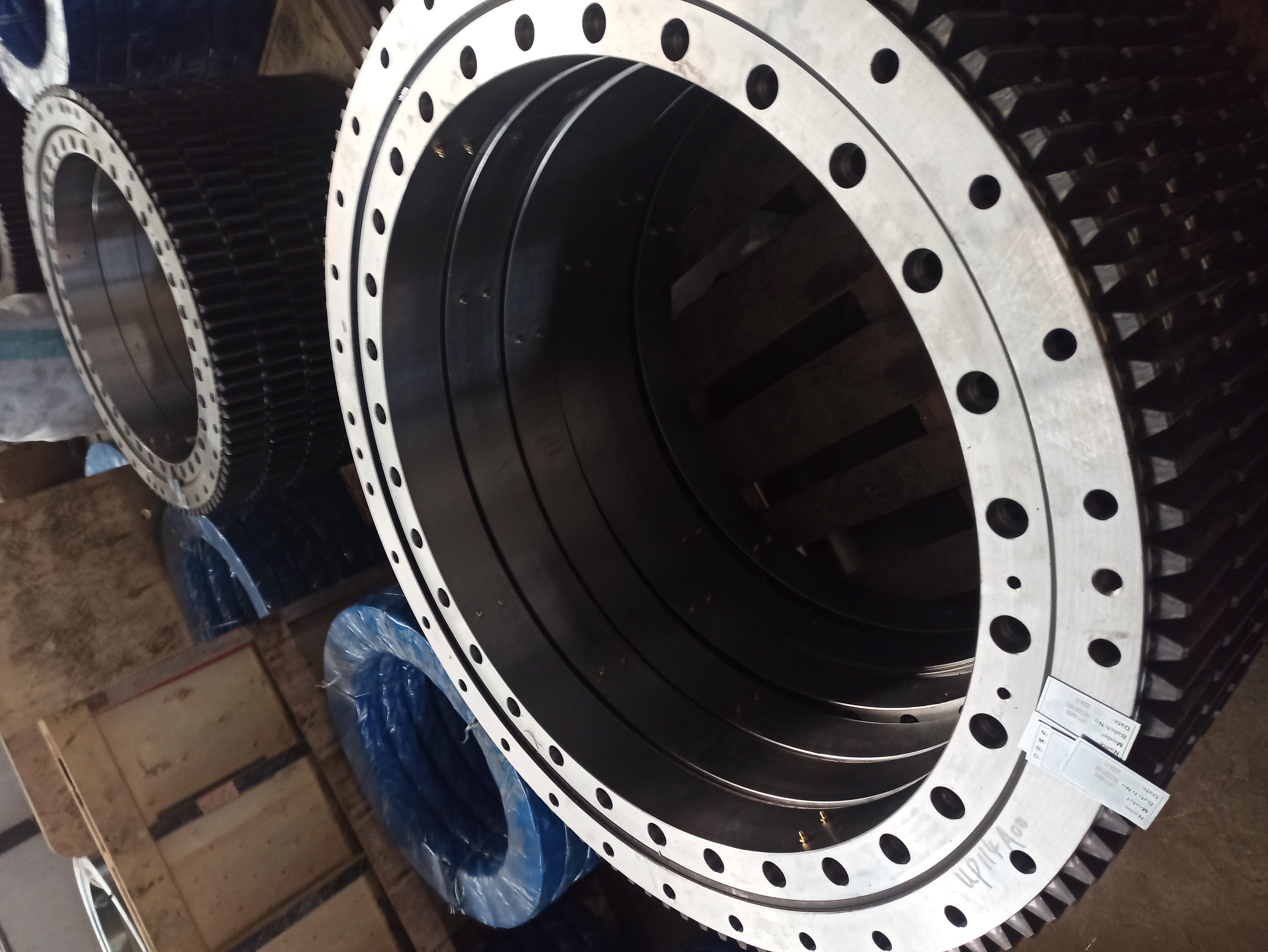

Slewing bearings you can choose with confidence

When performing maintenance work, first of all, pay attention to the risk of being dragged into the counter-rotating pinion, and the risk of crushing and shearing. When performing the following tasks, ensure that when starting the engine to perform necessary reversal and luffing movements, any maintenance personnel are not in the risk area between the main arm, the upper vehicle and the rolling plate, or between the lowering vehicle and the rolling plate. risk area, except for the crane operator (in the cab).

Check the bolts of the reversing support: 1. Before each operation of the crane or at least once a week, visually check the bolts on the reversing support; 2. After the first 100 operating hours of the reversing support, check whether the bolts are loose. Check again after 300 working hours; check every 500 working hours in the future; shorten the checking distance under severe working conditions.

If the bolts are found to be loose during inspection, please stop the construction and contact the local after-sales service department immediately. The factory or professional technicians will inspect and decide whether to disassemble and inspect the bearing immediately; 3. Inject the reversing bearing before installation. Full of lithium-based grease; 4. When replacing bolts, clean the bolts, apply thread fastening glue and tighten them; use the crane in accordance with the requirements of the operation manual and lifting function table, or check the fastening bolts regularly as required. The risk of bolt fatigue damage can be avoided.