Yaw Bearing For Wind Turbine Generator

- LYHGB

- Luoyang

- 45 days

- 1000 pcs/ month

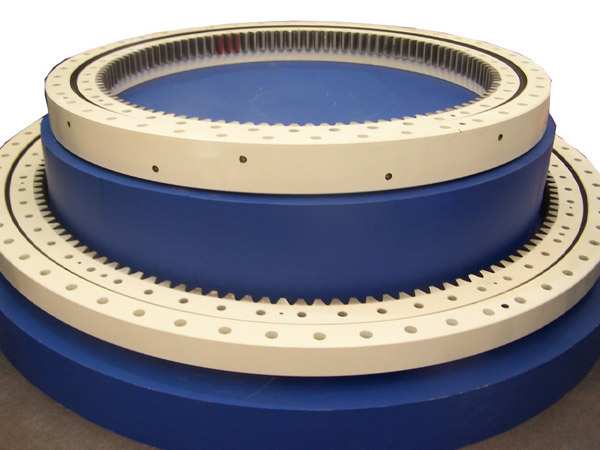

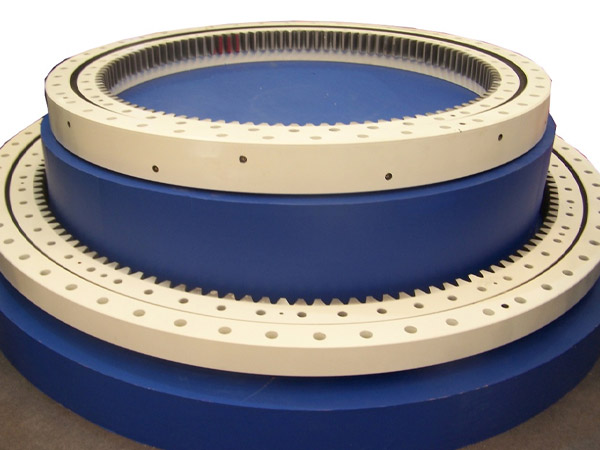

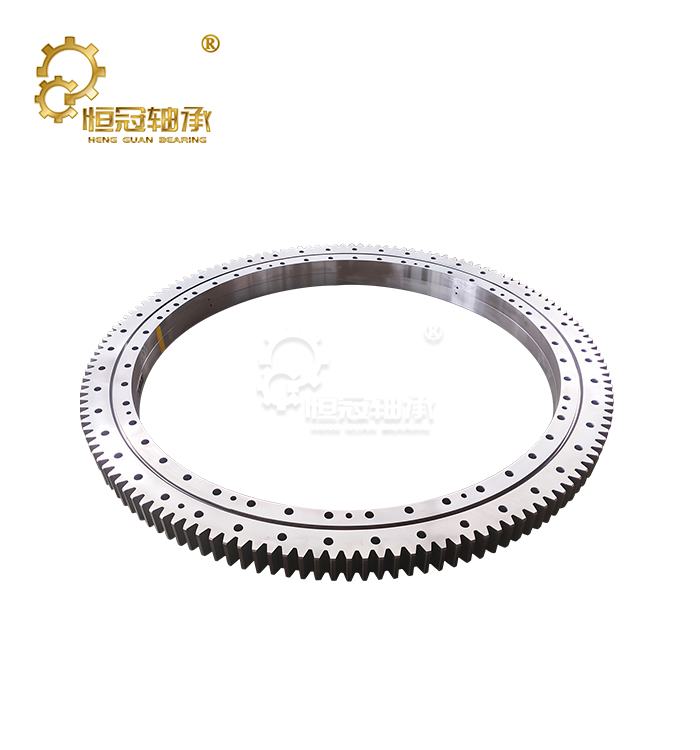

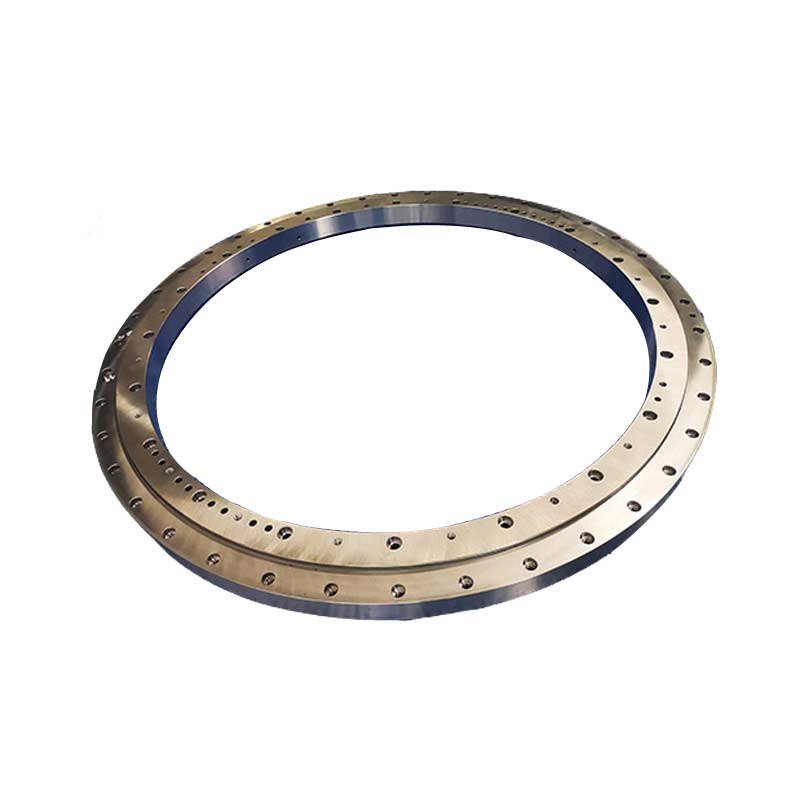

The wind turbine yaw bearing is installed at the connection between the tower and the cockpit, and the pitch bearing is installed at the connection between the root of each blade and the hub. Each wind turbine uses one set of yaw bearing and three sets of pitch bearing. The material of the yaw and pitch bearing rings is 42CrMo, the heat treatment adopts the overall quenching and tempering treatment, and the surface of the raceway is quenched. The force of yaw and pitch bearings is complex, and the impact and vibration are relatively large. Therefore, the bearing is required to withstand both impact and large load. The life of the wind turbine main engine requires 20 years, and the cost of bearing installation is relatively large, so the life of the yaw and pitch bearings is required to reach 20 years. The hardness of the bearing ring base is 240-280HB, which can withstand impact without plastic deformation. At the same time, the surface quenching hardness of the raceway reaches 55-62HRC, which can increase the contact fatigue life and ensure the service life of the bearing.

Yaw Bearing For Wind Turbine Generator

The yaw bearing is the most crucial and cost-intensive component of a yaw system found on modern horizontal axis wind turbines. The yaw bearing must cope with enormous static and dynamic loads and moments during the wind turbine operation, and provide smooth rotation characteristics for the orientation of the nacelle under all weather conditions. It has also to be corrosion and wear resistant and extremely long-lasting. It should last for the service life of the wind turbine) while being cost effective.

The wind turbine yaw bearing is installed at the connection between the tower and the cockpit, and the pitch bearing is installed at the connection between the root of each blade and the hub. Each wind turbine uses one set of yaw bearing and three sets of pitch bearing. The material of the yaw and pitch bearing rings is 42CrMo, the heat treatment adopts the overall quenching and tempering treatment, and the surface of the raceway is quenched. The force of yaw and pitch bearings is complex, and the impact and vibration are relatively large. Therefore, the bearing is required to withstand both impact and large load. The life of the wind turbine main engine requires 20 years, and the cost of bearing installation is relatively large, so the life of the yaw and pitch bearings is required to reach 20 years. The hardness of the bearing ring base is 240-280HB, which can withstand impact without plastic deformation. At the same time, the surface quenching hardness of the raceway reaches 55-62HRC, which can increase the contact fatigue life and ensure the service life of the bearing.

Slewing bearing for wind turbine is a kind of large bearing, mainly used for pitch and yaw system. It is complicated to load, and it is very difficult to disassemble and maintain. Therefore, the design and manufacture of wind power slewing bearing are strict. If non-standard customization is required, our company can provide technical support such as selection, design, calculation, etc.,