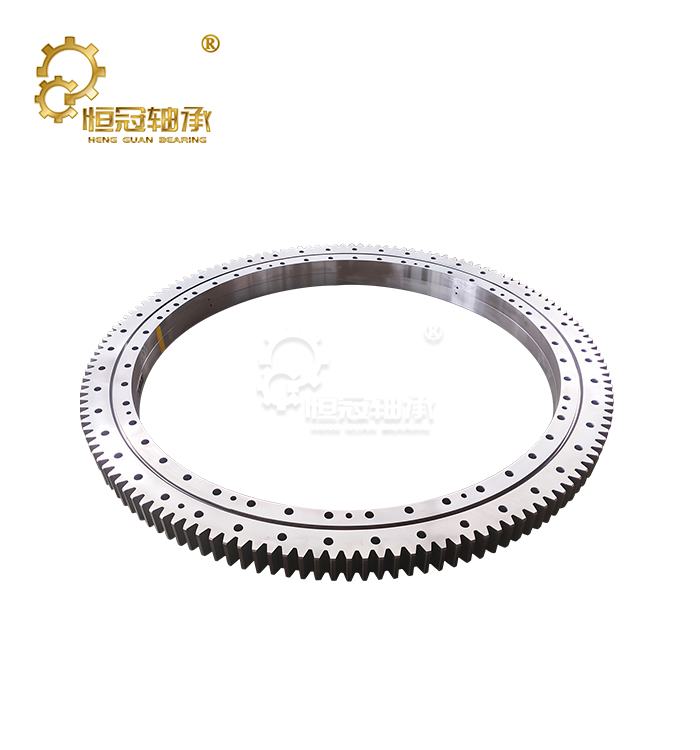

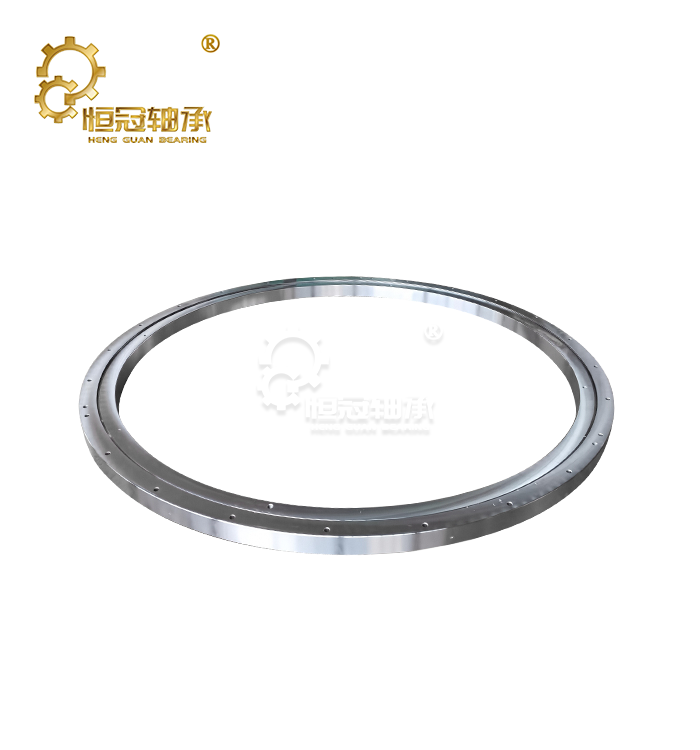

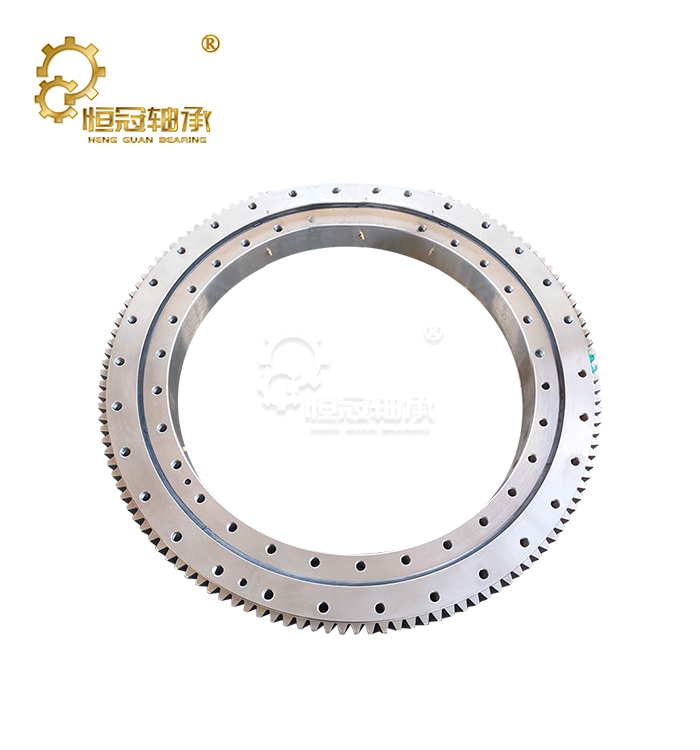

Welding Positioners Slewing Bearing

- LYHGB

- Luoyang, China

- 45 DAYS

- 4000 SETS/ MONTH

High-precision welding positioner slewing bearing: Providing precise and reliable core power for industrial automation

Product Model: Heavy-duty precision slewing bearing

Core Specifications: 1300×998×100(mm) (Custom sizes available upon request)

Material: 50Mn/42CrMo alloy steel

Axial clearance: 0.02-0.1mm (Customizable based on operating conditions)

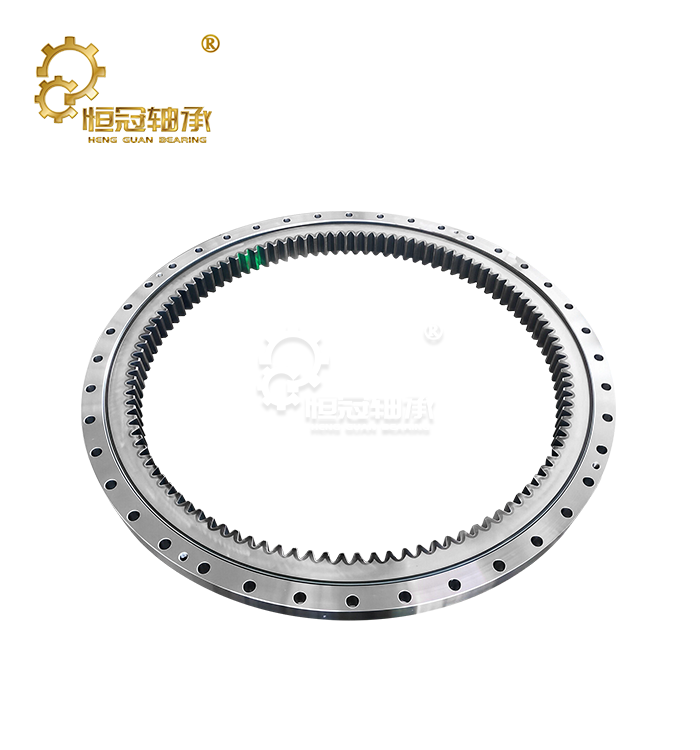

Gear surface hardening treatment: Yes

Product's core advantages

Designed specifically for heavy-duty welding positioners and industrial robots, it features a high-rigidity structure with dimensions of 1300×998×100mm, providing excellent load capacity and resistance to overturning moments. Precisely machined axial clearance is controlled within the range of 0.02-0.1mm, ensuring that rotational positioning repeatability meets industrial-grade requirements.

If you are looking for a suitable supplier please contact us!

We will provide you with a complete service

Email:bonnie@hgb-bearing.com

Wechat/Whatsapp/Call +86-13938815302

Double assurance through materials and manufacturing processes.

High-Strength Material: Made from high-quality 50Mn/42CrMo alloy steel, undergoing a special heat treatment process to achieve a perfect balance of high strength and toughness.

Gear Surface Strengthening Technology: The gear surface is treated with deep quenching, reaching a hardness of HRC55-60, significantly improving wear resistance and service life.

Wide Size Customization: Supports processing sizes ranging from 50-10000mm, meeting the diverse needs of applications from compact robots to large welding systems.

|

|

Precise application scenarios

Welding Automation Field

The rotary structure, specifically designed for welding positioners, maintains stable performance even in dry welding environments, enabling precise flipping and positioning of workpieces during the welding process, significantly improving welding quality and production efficiency.

Industrial Robot Integration

As the core rotating component of the robot's seventh axis, it provides smooth and precise rotational movement, supporting multi-angle and multi-position operations, expanding the robot's working range and application flexibility.

Precision Positioning System

In automated equipment requiring precise indexing and positioning, it ensures repeatable accuracy at each stop position, meeting the requirements of high-precision assembly, inspection, and processing applications.

Detailed explanation of technical characteristics

Precision Rotation Performance

Ultra-low backlash design: Axial backlash is minimized to as low as 0.02mm, ensuring smooth and stable rotation without wobbling.

High-rigidity structure: Optimized cross-section design minimizes deformation even under heavy load conditions.

Precise positioning capability: When combined with a servo drive system, it achieves precise control of angular position.

Durability and Reliability

Reinforced gear system: Hardened gear teeth significantly improve wear resistance and extend service life.

Optimized sealing design: Effectively prevents welding spatter and dust from entering, making it suitable for industrial environments.

Adaptability to harsh conditions: Tested under load and subjected to fatigue testing to ensure reliability in continuous production.

|  |

Application Conditions and Configuration Recommendations

Ideal Working Conditions:

Precise rotation and positioning control requirements

Medium to heavy-duty welding and assembly applications

Integration into automated production lines

Industrial environments requiring continuous and stable operation

System integration support

Standard interfaces and customized connection solutions are provided for easy integration into various welding positioners, industrial robot bases, and automated rotary platforms, compatible with mainstream drive control systems.