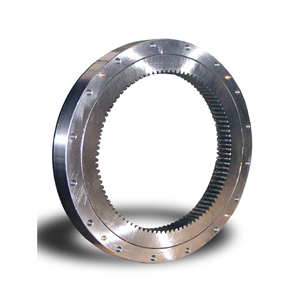

crane slewing bearing

-

5-meter toothless large slewing bearing

The double-row ball gearless slewing bearing is an important mechanical component. Its design feature is that it has two rows of steel balls, which can withstand large axial forces and tipping moments. This product is particularly suitable for medium and large diameter tower cranes, truck cranes and other loading and unloading machinery.

customized slewing bearing Professional factory slewing bearing excavator swing bearing large slewing bearingEmail Details -

Customizable Flange plate+Slewing bearing

In the production process of slewing ring bearing, whole process inspection is implemented strictly to ensure that each set of products are qualified. For high-precision products, precise grinding is used to effectively control the parameters of ring ellipse, wall thickness and flatness, so as to ensure that the precision of finished products meets the requirements of standards or customer drawings.

Flange plate and Slewing bearing slewing bearing manufacturer turntable bearing custom slewing bearingEmail Details -

Customizable special-shaped slewing bearing

We provide customizable special-shaped slewing bearings, which are tailored to meet the specific needs of different mechanical equipment. Our special-shaped slewing bearings have the characteristics of high precision, high load capacity and low friction coefficient, ensuring the stable operation of the equipment in complex environments.

Email Details -

High technology high quality customizable slewing rotary bearings

1.The three row roller type rotary bearing has three seat rings, with the upper, lower, and radial raceways separated, and the load of each row of rollers can be accurately determined 2.Capable of withstanding various loads simultaneously, with large axial and radial dimensions and a sturdy structure

Email Details -

Slewing bearing loading and unloading machinery

The slewing bearing of loading and unloading machinery, especially the double-row ball slewing bearing, is a high-precision and high-load-bearing mechanical component. This product has a unique structural design and excellent performance characteristics, and plays an indispensable role in various types of loading and unloading machinery.

slewing bearing loading machines high quality slewing bearing double row ball slewing bearing truck crane slewing bearingEmail Details -

Crane heavy duty slewing bearing

A crane refers to a multi action lifting machinery that vertically lifts and horizontally transports heavy objects within a certain range. Also known as bridge crane, high-altitude crane, or crane. The slewing bearings used in cranes are mainly heavy-duty slewing bearings, which need to withstand large axial forces and overturning moments. The main function is to support the upper mechanism and control its rotation. The electric motor or reducer drives the small gear to rotate, and the small gear drives the slewing support to rotate, causing the upper mechanism connected to it to rotate accordingly.

Email Details -

Carrying large customizable heavy duty machinery slewing bearings

The single-row crossed roller slewing bearing is composed of two seat rings. It has a compact structure, light weight, high manufacturing precision, small assembly clearance, and high requirements for installation accuracy. The rollers are arranged in a 1:1 cross and can bear the bearings at the same time. It has axial force, overturning moment and large radial force, and is widely used in lifting, transportation and engineering machinery products.

Email Details -

Customizable high-quality truck crane slewing bearings

Double row ball slewing bearing is a special kind of slewing bearing. Its design principle is as follows: Structural composition: Double volleyball slewing bearing consists of two volleyball balls and inner and outer rings. Volleyball balls are placed between the inner and outer rings and can withstand axial and radial loads. The inner and outer rings are fixed and can rotate relative to each other.

truck crane slewing bearing customizable slewing bearing large swing bearing loading machines slew bearingEmail Details -

high quality customizable construction machinery slewing bearings

The single-row four-point contact ball slewing bearing is composed of two seat rings. It has a compact structure and light weight. The steel balls are in four-point contact with the arc raceway and can withstand axial force, radial force and overturning moment at the same time. Construction machinery such as rotary conveyors, welding operators, small and medium-sized cranes and excavators can all be used.

high quality slewing bearings construction machinery slewing bearings single row four point contact ball slewing bearing Slewing bearing manufacturerEmail Details