Innovative Slewing Bearing Solutions for the Wind Energy Industry

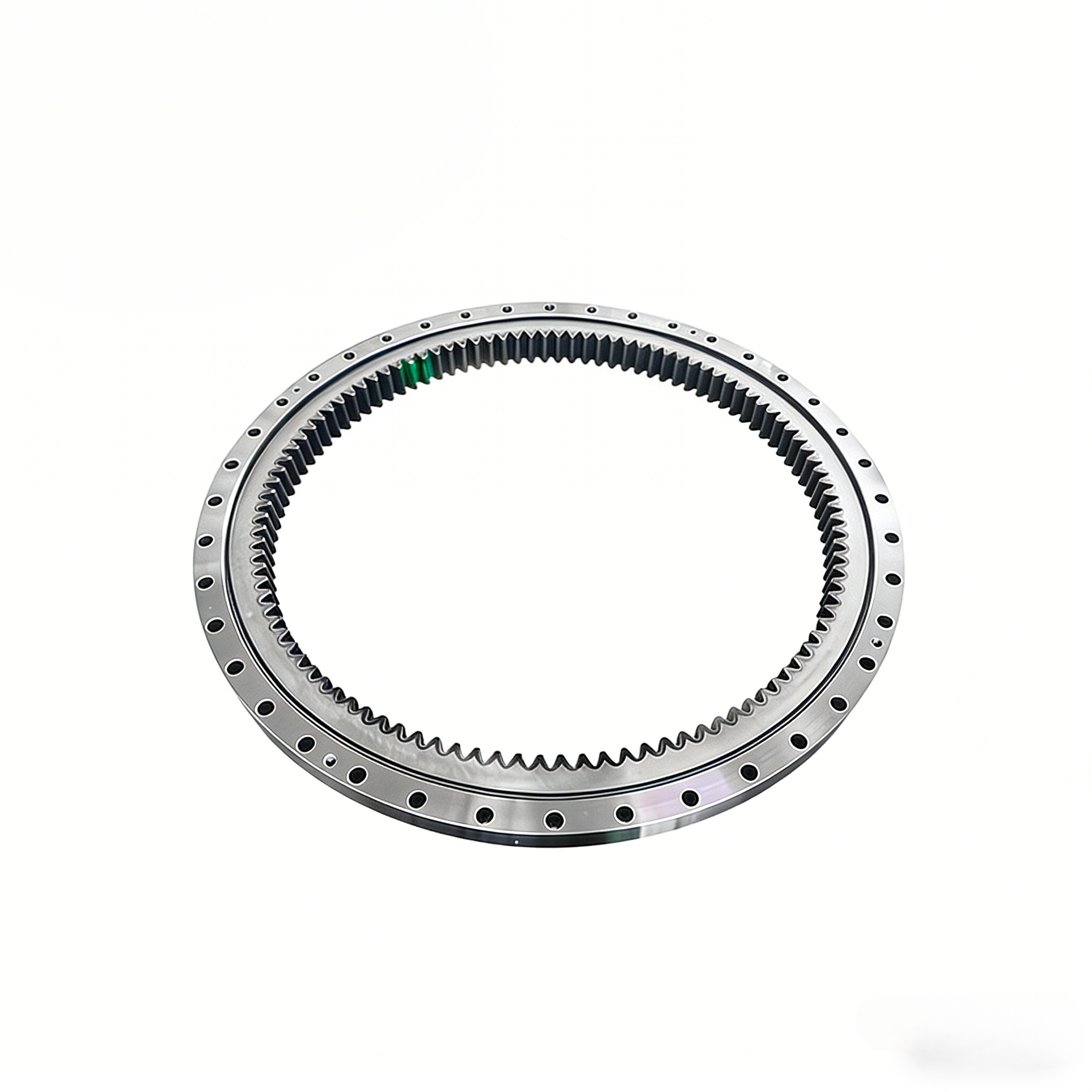

The global transition to renewable energy has placed wind power at the forefront of sustainable electricity generation. As wind turbines grow in size and capacity to enhance energy output and efficiency, the mechanical components that enable their operation face unprecedented demands. Among these critical components, slewing bearings play a pivotal role. They are the robust, precision-engineered rings that facilitate the rotation of the nacelle (yaw bearings) and the adjustment of blade pitch (pitch bearings). The evolution of the wind industry toward larger rotors, taller towers, and offshore installations necessitates continuous innovation in slewing bearing design, materials, and manufacturing. This article explores the cutting-edge solutions revolutionizing slewing bearings for the wind energy sector.

1. The Growing Demands on Slewing Bearings

Modern wind turbines, particularly those offshore, operate in harsh environments characterized by extreme loads, unpredictable wind gusts, saltwater corrosion, and limited accessibility for maintenance. Slewing bearings must withstand:

Higher Static and Dynamic Loads: Larger rotor diameters and heavier nacelles increase bending moments and axial/radial forces.

Complex Load Combinations: Bearings experience simultaneous tilt moments, axial forces, and radial forces from wind, gravity, and turbine dynamics.

Enhanced Durability and Lifetime: Design lifespans of 25+ years, with minimal maintenance, are essential for economic viability.

Harsh Environmental Conditions: Offshore applications demand superior corrosion resistance and sealing against moisture and contaminants.

2. Key Areas of Innovation

To meet these challenges, manufacturers and engineers are driving innovation across several dimensions:

a. Advanced Materials and Heat Treatment

Clean Steel Grades: The use of ultra-clean, homogeneous steel with minimized inclusions improves fatigue strength and fracture toughness.

Innovative Heat Treatments: Case hardening processes like carburizing are being refined to create a hard, wear-resistant surface while maintaining a tough, ductile core. New techniques, such as deep-hardening processes, optimize the material properties for specific load zones within the bearing.

Corrosion Protection: Beyond standard coatings, advanced solutions include integrated sealing systems with multi-layered protective coatings and the use of stainless steels for critical components in highly corrosive environments.

b. Intelligent Design and Digitalization

Integrated Sensor Technology: The development of "smart bearings" equipped with embedded sensors (strain gauges, temperature, and vibration sensors) allows for real-time condition monitoring. This data enables predictive maintenance, preventing catastrophic failures and optimizing service intervals.

Topology Optimization & Lightweighting: Using Finite Element Analysis (FEA) and generative design software, engineers create bearing geometries that optimally distribute material where stresses are highest, reducing weight without compromising strength or stiffness.

Integrated Functionality: Bearings are increasingly designed as system components, incorporating features like built-in lubrication channels, sealing grooves, and mounting structures to simplify assembly and improve reliability.

c. Enhanced Sealing and Lubrication Systems

Multi-Barrier Sealing: Advanced multi-lip seal designs, often combining different elastomer compounds, provide superior protection against water, salt, and particulate ingress.

Active Lubrication Systems: Centralized, automated lubrication systems ensure consistent and optimal grease distribution to all raceways, reducing wear and manual intervention needs. New, high-performance greases are formulated for extended service life and extreme pressure tolerance.

d. Specialized Solutions for Offshore & Floating Wind

The offshore frontier presents unique challenges. Innovations here include:

Corrosion-Resistant Packages: Comprehensive protection systems combining material choice, coatings, and sealing.

Larger Diameter Bearings: For the next generation of 15+ MW turbines, bearings exceeding 4 meters in diameter are being developed.

Bearings for Motion Compensation: For floating offshore wind platforms, bearings must accommodate additional dynamic movements (pitch, roll, heave), requiring novel design approaches to handle multi-directional motions and loads.

3. The Benefits of Innovation

These advancements translate into direct value for wind farm operators and the industry:

Increased Reliability & Availability: Reduced unplanned downtime maximizes energy production.

Lower Levelized Cost of Energy (LCOE): Achieved through longer service life, reduced maintenance costs, and higher turbine efficiency.

Enabling Technology: Makes the development of larger, more powerful turbines technically and economically feasible.