How often should slewing bearing grease be refilled?

How often should slewing bearing grease be refilled?

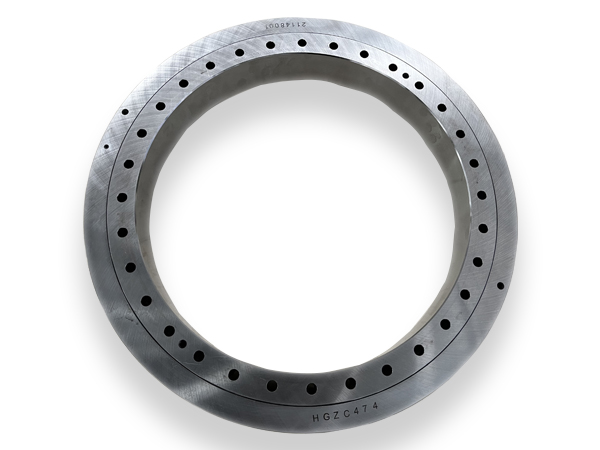

The slewing bearing is an important component of the mechanical slewing structure. To maintain the high-efficiency operation of the machine under high load and harsh environment conditions, the good performance of the slewing bearing is one of its important basic guarantees.

Wear is one of the common causes of failure of mechanical components. Therefore, in order to reduce the wear rate of the slewing bearing, it is necessary to do the corresponding lubrication work. In order to ensure the effective and reliable operation of the bearing, the bearing must have sufficient Lubrication, lubrication is an essential part of bearings. Therefore, the filling of grease plays an important role in the normal use of the slewing bearing. So, do you know how often the slewing bearing grease is filled?

1. Filling of slewing bearing grease

1) Filling with grease

After the bearing is installed, it needs to be supplemented with grease before running. When filling the grease, the bearing should be rotated while filling to make the grease evenly distributed until the grease overflow is observed at the lip of the sealing strip on the bearing. When the grease overflows from the seal, it means that the filling is completed, and the overflowing grease will form a film and act as a seal.

2) Daily automatic grease injection

After grease injection, the automatic grease injection system can be turned on, and a certain amount of grease can be injected every day (regularly) to meet the normal use of the bearing. The grease injection amount for two months should at least reach the internal cavity volume value of the slewing bearing. Bearings, on the one hand, pay attention to the consumption of grease, and on the other hand, regularly check the oil circuit to prevent leakage.

Every three months or so, a concentrated grease injection should be carried out inside the slewing bearing, and a large amount of grease should be injected into the upper grease injection hole until the lip of the upper sealing strip evenly overflows with fresh grease.

2. Three row roller slewing bearing grease

The bearing structure has the largest cavity in the upper row of the main force bearing raceway, and the upper row of raceway grease will move to the lower row of raceways during operation. The amount of grease injected into the upper row should be appropriately increased. 130% of the fat injection volume.

3. What are the commonly used greases for slewing bearings?

The commonly used lubricating greases are calcium-based grease, lithium-based grease, aluminum-based grease and high-temperature grease, etc. The user can choose the appropriate grease according to the specific situation.

The above is the answer to how often the slewing bearing grease should be filled. Timely filling of the grease is very important, but regular cleaning is also very important. Before the slewing bearing is installed, it is necessary to clean the plane supporting the car to remove the oil stains, Burrs and some debris are removed, and there is a clean working environment before installation. In addition, new grease must be added before and after the slewing bearing stops running for a long time. The grease should be extreme pressure lithium base grease or lithium base grease containing molybdenum disulfide.